Model No.: USA-100

Brand: UniSite

Type: Heavy

Tolerance: High Accuracy(ISO2768, ISO5817, ISO13920)

Inspection: Material, Construction, Dimension, Welding Seam, N

Certificate: BV CCS ISO

Dimension: As Per Drawing, As Large As We Can

Standard: AISI, ASTM, BS, DIN, GB, JIS, EN

Application: Liner For Dredging And Dredger Parts

Material: Raex400 ,raex500 ,NM400,NM500 Or Other Materials

OD: 800 - 2000 Mm

Wear Resistant Steel Pipe: Wear Resistant Steel Piping

Packaging: bulk package and bulk vessel transportation container package and container transportation

Transportation: Ocean,Land

Place of Origin: china mainland(zhejiang)

Certificate: BV/ISO/CCS

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Because the tube has wear resistance, corrosion resistance, heat resistance, so it can be widely used in electric power, metallurgy, mining, coal, chemical industry as a transport sand, stone, coal and coal ash, aluminum liquid grinding granular material and corrosive medium, is an ideal wear-resistant and corrosion of pipeline.

Performance characteristics

1. excellent wear resistance, continuous use for more than 10 years time

Wear-resisting bend - centrifugal casting composite ceramic corundum ceramics in 910 million KW unit using coal ash up to 45%, tubes per hour feeding 42 tons, the use of 24 months wear out 0.2mm in pneumatic conveying of dry ash, 74 tons /, velocity of 20m / s, 28% concentration, position in the corner of the gray. The use of 12 months wear out 0.15mm

Wear resistant elbow - stick ceramic plate and the Central South University of technology of Powder Metallurgy Research determined, the wear resistance of the ceramics is equivalent to 266 times of manganese steel, 171.5 times of high chromium cast iron, excellent wear resistance. Wear resistant elbow in the application of milling system greatly reduced the wear of equipment, according to more than ten years of experience in the field of operation, durability of at least 10 years or more, reduce maintenance frequency and cost.

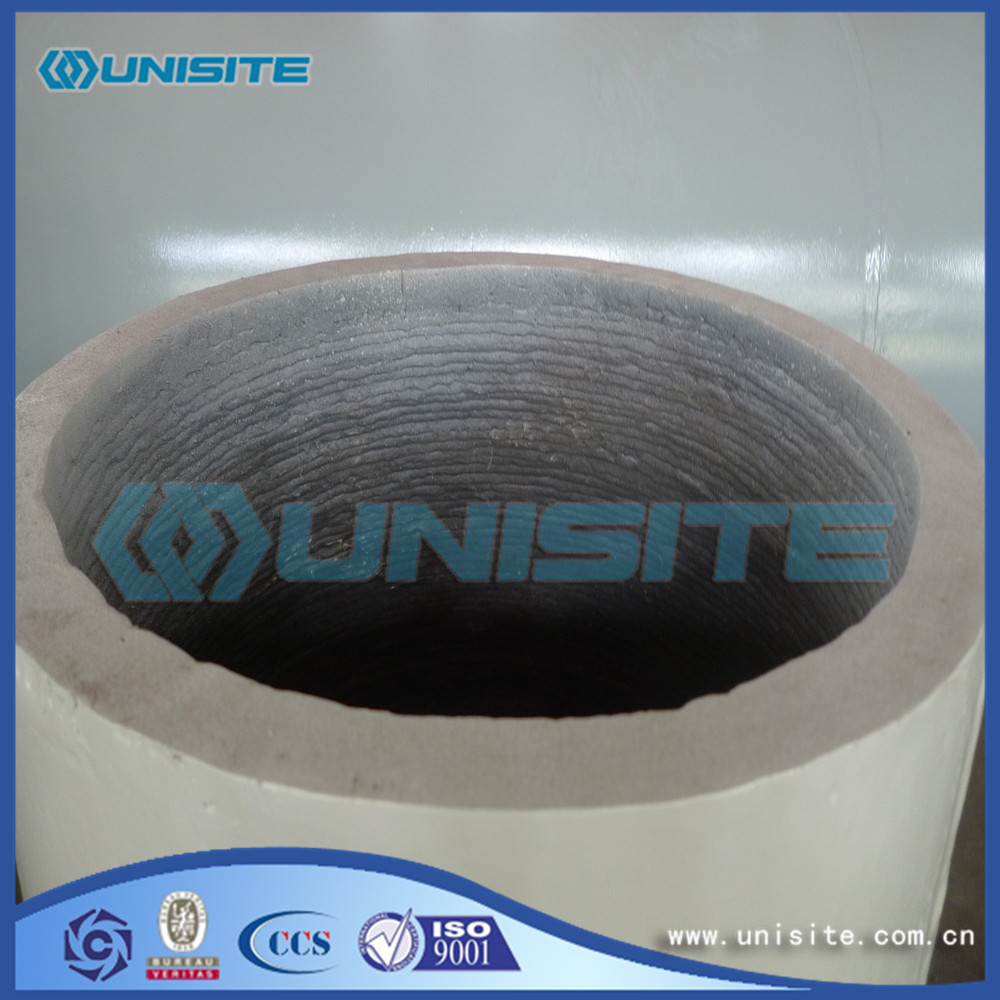

2. ceramic lined with high strength, high hardness, light weight

Centrifugal casting composite ceramic, corundum layer hardness up to HV1100-1400, equivalent to tungsten cobalt hard alloy. The weight of the composite ceramic bend is only the 1/4 of wear-resistant steel elbow, easy to install and replace.

The hardness of corundum ceramics is HRA80-85, which is much higher than that of wear resistant steel and stainless steel. The density is only half of the steel, and the weight of the ceramic elbow is only 1/3 of the wear-resistant steel elbow.

3 installed firmly, heat resistance, corrosion resistance

Centrifugal casting composite ceramics, ceramic Steel Pipe in the melting point of 2045 degrees, corundum and steel due to the special structure of the process, the stress field is also special. When temperature is increased to 900 DEG C, the ceramic pipe into the cold water, repeatedly, ceramic layer does not crack or crack showed that is unparalleled in the ordinary ceramic thermal shock resistance, ceramic pipe, the inner dense alpha type aluminium oxide, acid degree 96-98%. 3. oxidation 2 aluminium oxide, and acid, alkali, salt were not chemical reaction. Three aluminum oxide is an inorganic material, in the light, heat, oxygen and other natural environment for a long time, there is no deterioration of the performance (that is, aging) problem. The corrosion resistance of ceramic tubes is ten times higher than that of stainless steel.

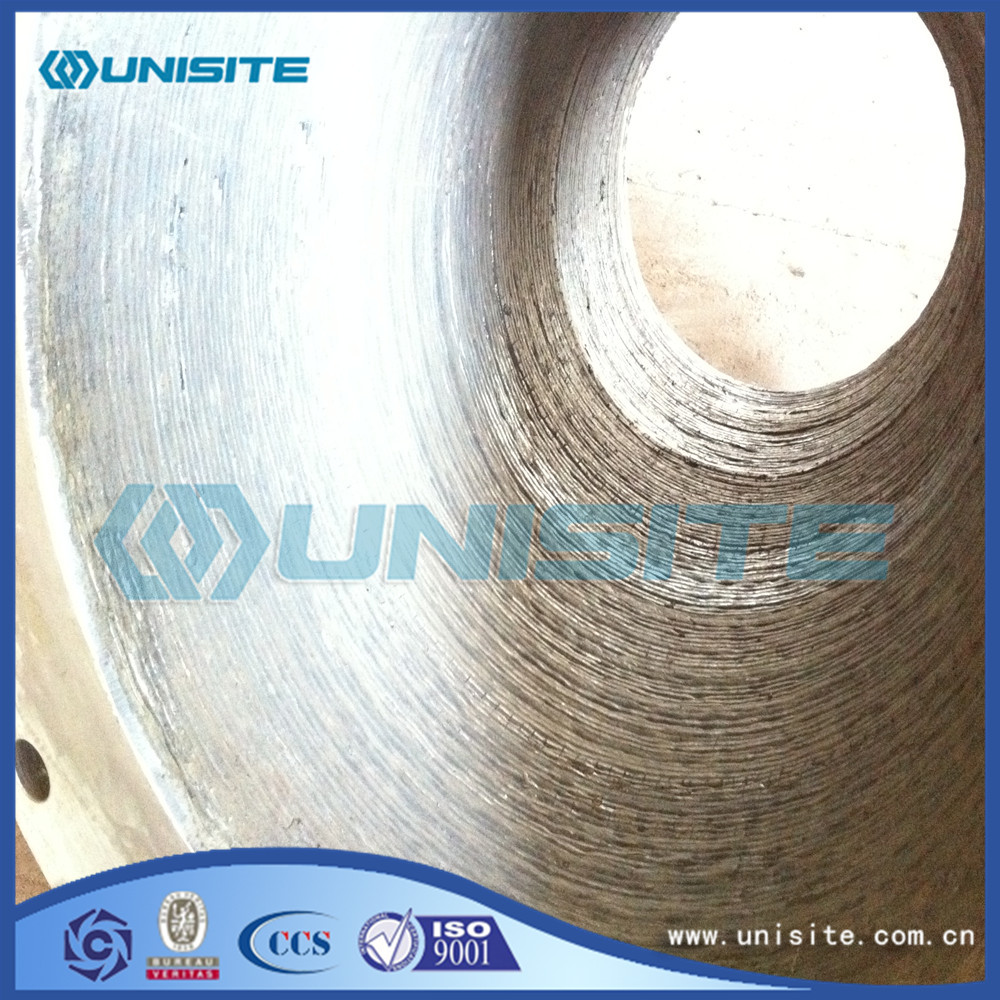

Ceramic pieces are installed on the inner wall of elbow by using high temperature inorganic adhesive. Company and Tsinghua University fine ceramic State Key Laboratory of joint development of the adhesive, strong adhesion, high temperature resistance, aging resistance, to ensure that will never fall off, Dongfang Hitachi and other boiler manufacturers in the burner installed ceramic paste are the glue. The installation technique is simple and reliable. Ceramic belongs to inorganic material, does not have the oxidation corrosion, acid and alkali corrosion.

4. the inner wall is smooth, does not block the powder material

Centrifugal cast composite ceramics belong to the overall ceramic, there is no gap, the surface is smooth, does not exist inside the ceramic high bottom view.

After high temperature sintering, the structure is compact, and the surface is smooth and smooth after the grinding. The placement process strictly in accordance with the & laquo; work instruction & raquo; ensure the smooth transition of the tiles, height difference is less than 0.5mm, posted a ceramic pipe inner wall smooth smooth without blocking powder.

ISO9001-2008/CCS; BV manufacturer capability qualification.

Taken part in the CHINA DREDGING ASSOCIATION

Quality, health, safety and environment (QHSE)

Production guidelines

In-house safety training to our staff

Checking all the production equipment periodically

Preventing pollution, accidents and health hazards, auditing

Accessories of our floating pontoon/ dock/platform/Barge

A. Main

Flanges

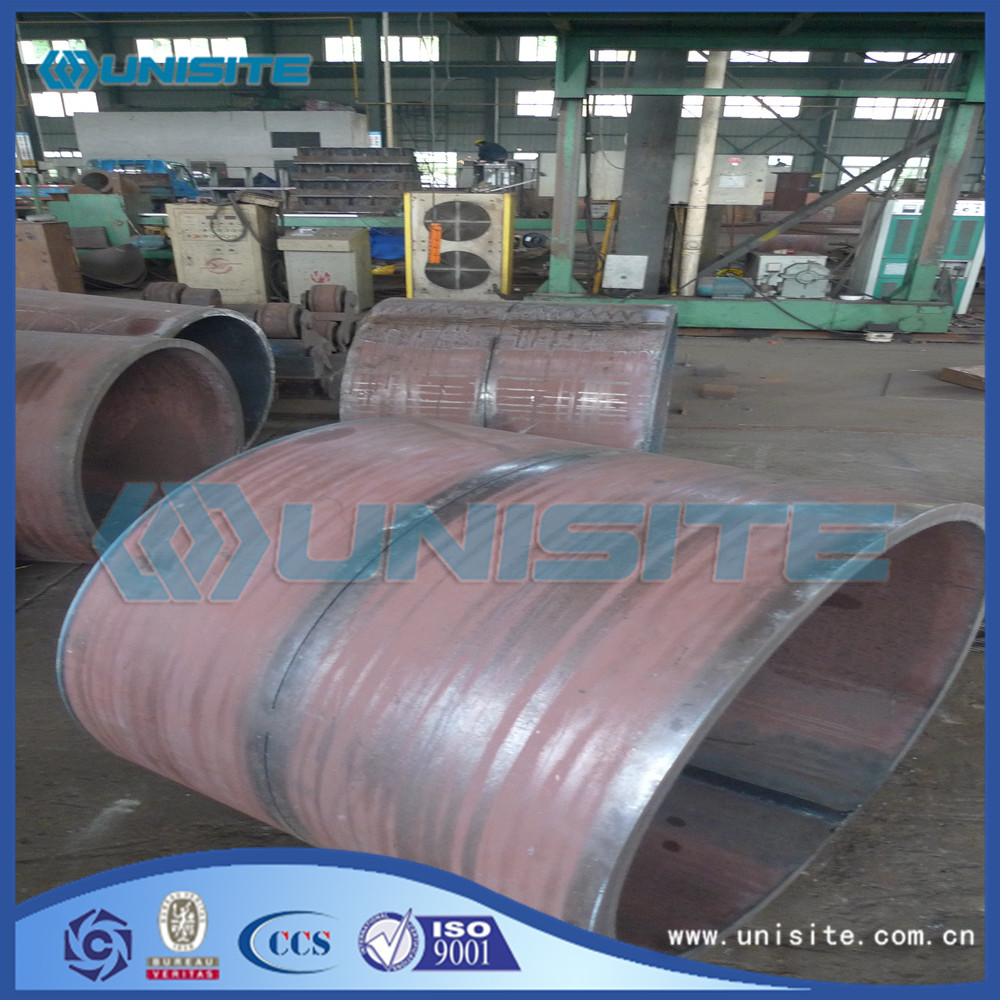

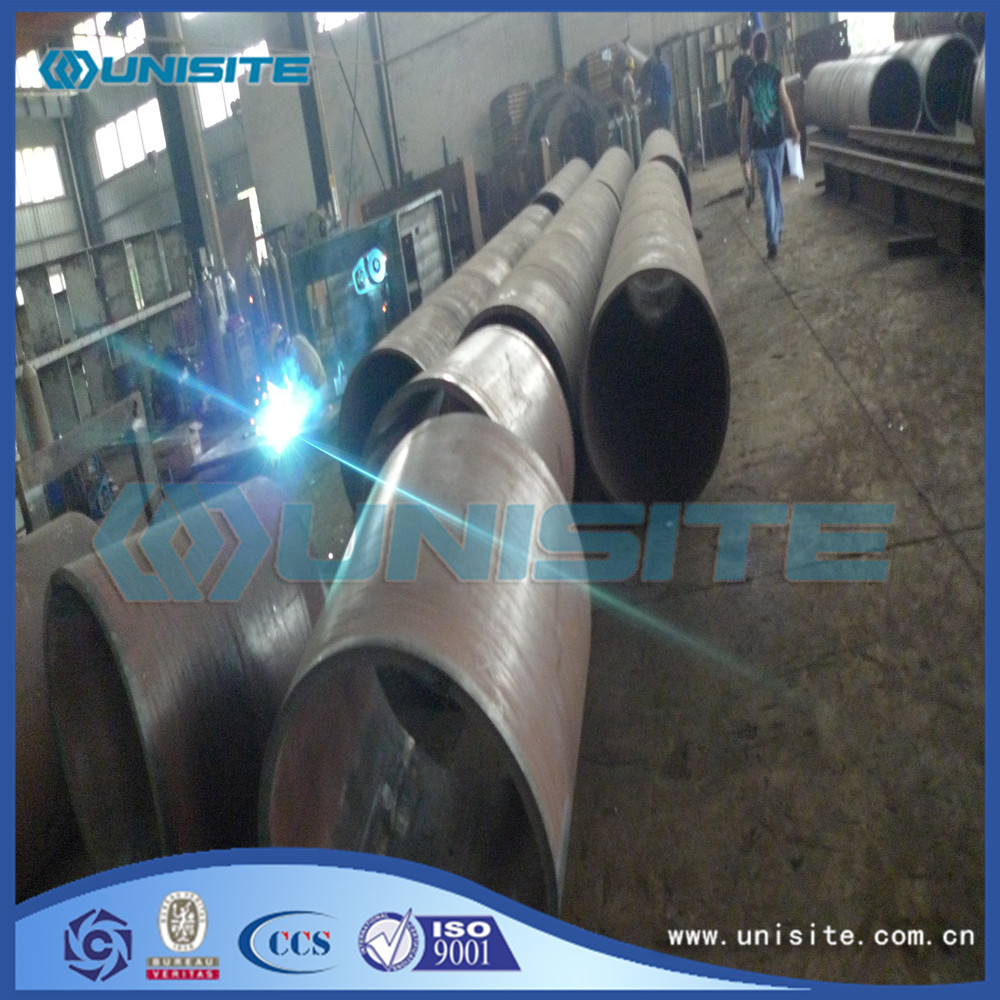

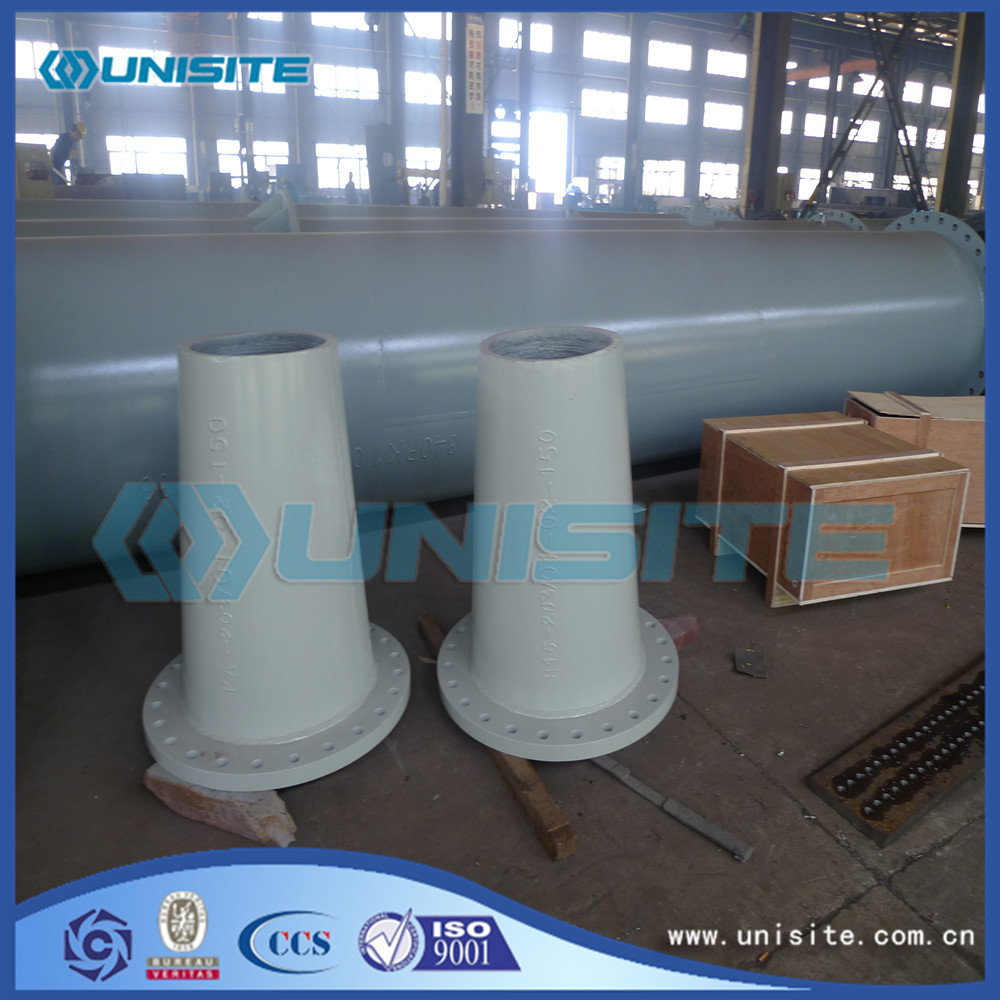

Photos of our Wear resistant steel loading piping

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Structural Pipes > Wear Resistant Pipe