Model No.: USA-102

Brand: UniSite

Type: Heavy

Tolerance: High Accuracy(ISO2768, ISO5817, ISO13920)

Inspection: Material, Construction, Dimension, Welding Seam, N

Certificate: BV CCS ISO

Dimension: As Per Drawing, As Large As We Can

Standard: AISI, ASTM, BS, DIN, GB, JIS, EN

Application: Liner For Dredging And Dredger Parts

Material: Raex400 ,raex500 ,NM400,NM500 Or Other Materials

OD: 800 - 2000 Mm

Welded Wear Resistant Pipe: Wear Resistant Welded Pipes

Packaging: bulk package and bulk vessel transportation container package and container transportation

Transportation: Ocean,Land

Place of Origin: china mainland(zhejiang)

Certificate: BV/ISO/CCS

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

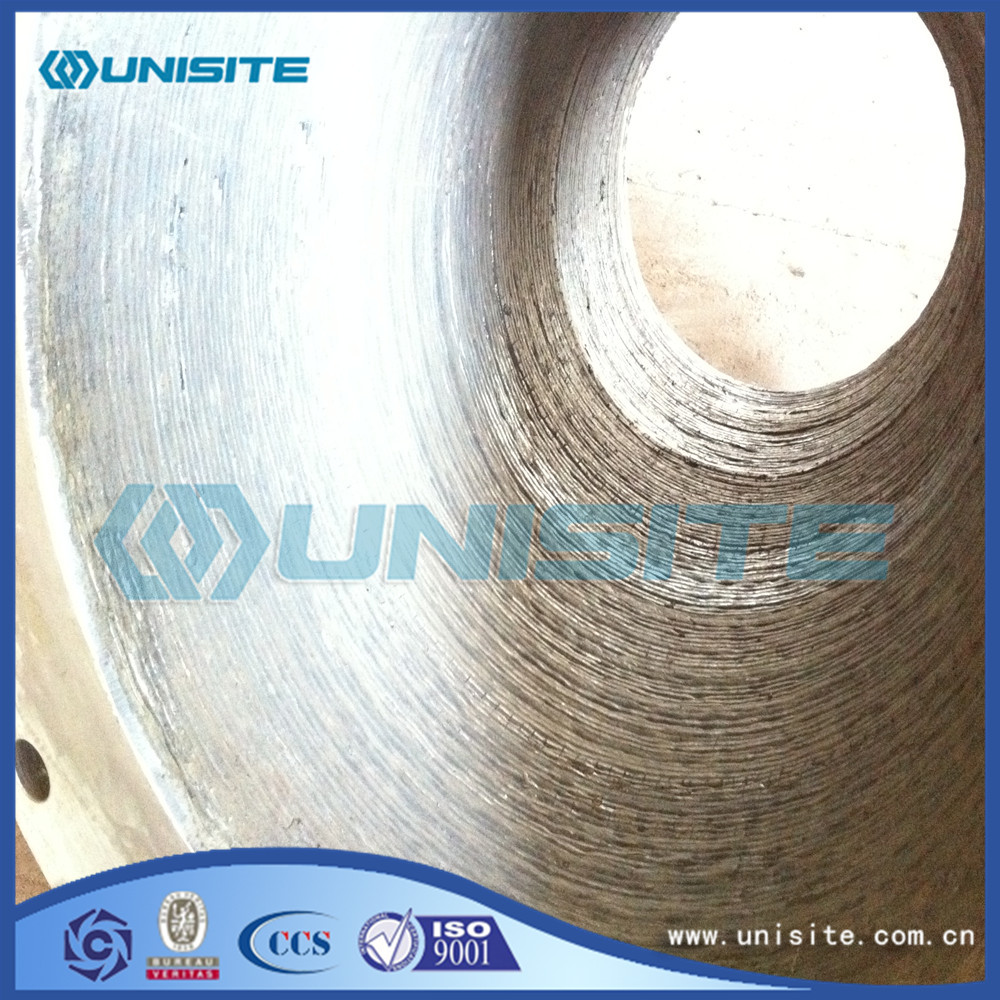

Point welding card wear-resisting pipe is resistant high tenacity viscose intermediate belt hole of alumina ceramics is pasted on the inner wall of the pipe and welding process through a small hole ceramic firmly welded on the inner wall of Steel Pipe. In order to protect the solder joint, the ceramic cap is screwed onto the top of the solder joint. Each tile not only press each other mutual inserted and each porcelain formation trapezoid angle, so that the ceramic block between tight junction and gap.

The specifications of our Wear Resistant Pipe

A. General

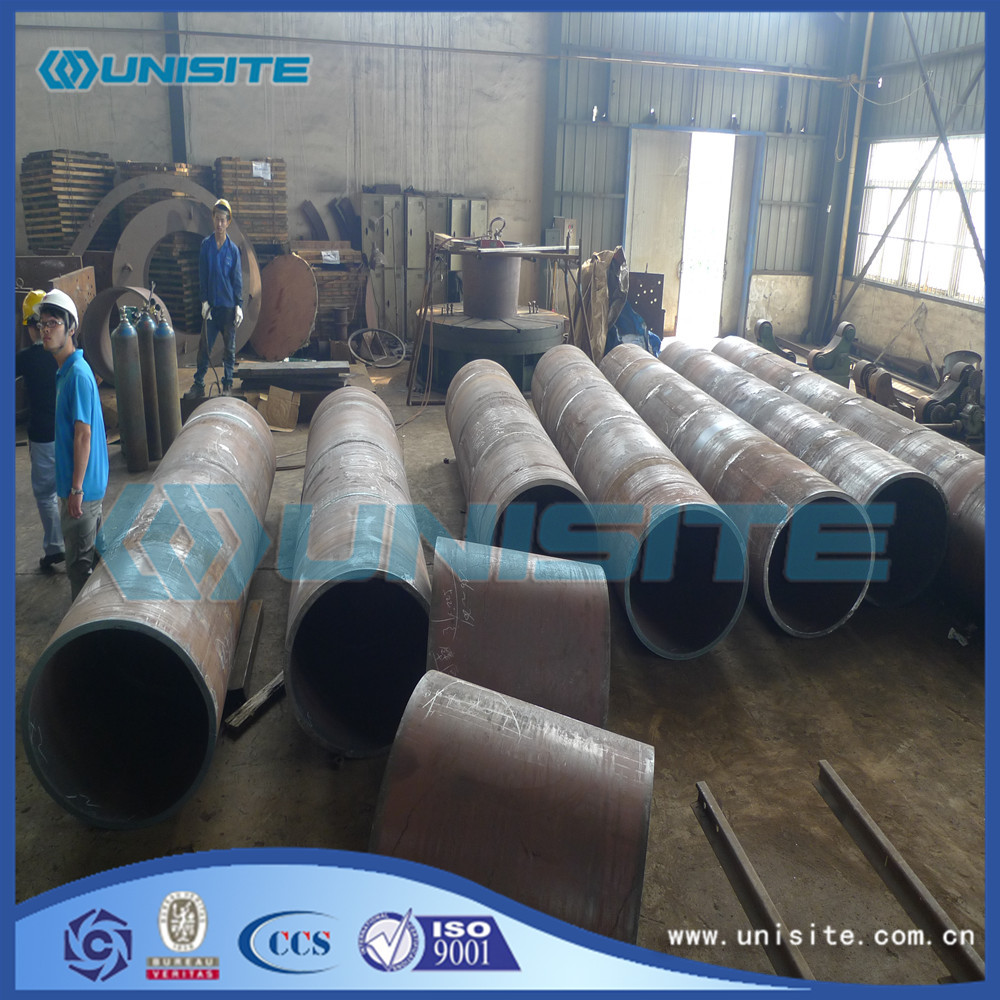

High accuracy, fully welded, rolling construction can be used for liner for dredging and Dredger parts

Using with high grade wear-resistant material or using with wear-resistant welding material, long service life is workable.c

B. Construction and procedure

The construction is to be built according to the drawing dimension

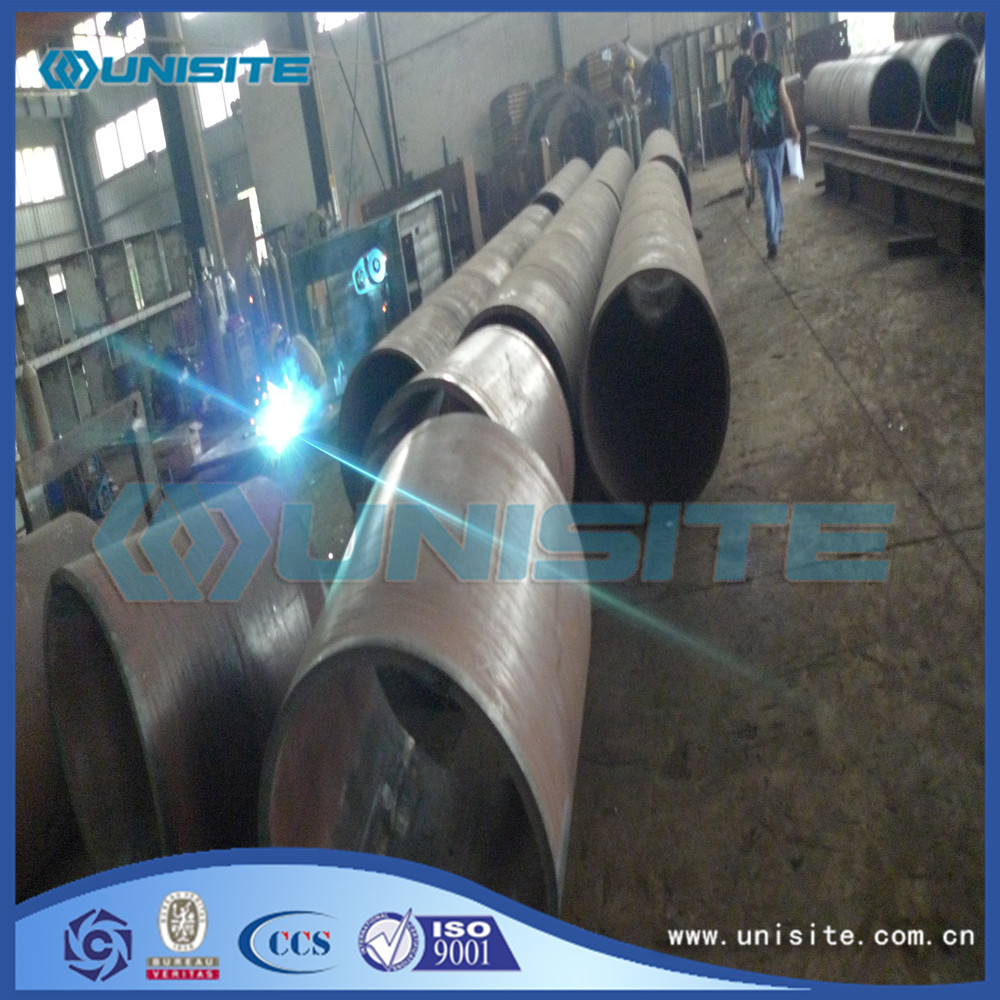

Cutting-Crimping press-Rolling-Adjusting-Tack welding-SAW-100%UT-Rounding-Marking

C. Materials

raex400 ,raex500 ,NM400,NM500 or other materials meet the standards GB/T24186-2009

D. Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

Welding seam preparation, welding method, welding material and consequent preheating temperature acc. to UniSite standards and approved by clients.

E. Workmanship

The workmanship have good marine practice. Care are taken to ensure fair lines, smooth surfaces and neat welding.

F. Main particulars

|

| MAIN PARTICULARS |

| Tolerance | High accuracy(ISO2768, ISO5817, ISO13920) |

| Material | raex400 ,raex500 ,NM400,NM500 or other materials meet the standards GB/T24186-2009 |

| Dimension(L*B*H) | As per drawing, as large as we can |

| thickness | 8-35mm |

| Coating | Sa2.5 blasted and two or three layers painted with highest quality |

| Marking | as per clients' requirements |

| Inspection | material, construction, dimension, welding seam, non defective test, paint inspection |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Certificates

- Material certificates by a classification society

- Inspection protocol

- NDT reports

- Fixed certificate: ISO9001, BV certificate, CCS certificate

Photos of our Wear resistant steel plates pipe

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Structural Pipes > Wear Resistant Pipe