Model No.: USA-099

Brand: UniSite

Type: Heavy

Tolerance: High Accuracy(ISO2768, ISO5817, ISO13920)

Inspection: Material, Construction, Dimension, Welding Seam, N

Certificate: BV CCS ISO

Dimension: As Per Drawing, As Large As We Can

Standard: AISI, ASTM, BS, DIN, GB, JIS, EN

Application: Liner For Dredging And Dredger Parts

Material: Raex400 ,raex500 ,NM400,NM500 Or Other Materials

OD: 800 - 2000 Mm

Steel Wear Resistant Pipe: Steel Wear Resistant Loading Pipes

Packaging: bulk package and bulk vessel transportation container package and container transportation

Transportation: Ocean,Land

Place of Origin: china mainland(zhejiang)

Certificate: BV/ISO/CCS

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Wear-resistant elbow can get the favor of the market and continue to replace some traditional abrasion proof material, the fundamental reason lies in the its superior product quality, and in with the traditional anti abrasive materials, such as cast stone, cast steel and ceramic material has many advantages compared to.

Review

Wear resistant industrial pipe wear has been a factor in the safe and civilized production, with the continuous development of science and technology, innovation of materials appeared cast stone, cast steel, alloy, ceramics bonded and materials. Which alumina ceramic lined pipe with high wear resistance, high hardness, oxidation resistance, resistant corrosion and high resistance to high temperature strength properties has become a kind of the most widely used wear-resistant materials, takes up about 80% of the world special ceramics market share (wear-resistant materials).

The hardness of the fused alumina layer is as high as 1100 - 1500 (90-98), which is equivalent to the hard gold of tungsten and cobalt. The wear resistance is more than 20 times higher than Carbon Steel Pipe, and it is superior to the performance of corundum grinding wheel which is bonded together. At present, Shandong Huaxing Electric Auxiliaries Co., Ltd. is the production of ceramic lined composite Steel Pipe using dozens of thermal power plant practice show that the ceramic lined composite steel pipe abrasion resistant ability is high, the fluid erosion resistant ability strong.

In the primary air pipe, the wear of the elbow is the fastest, and the wear resistance of the ceramic lined composite Steel Pipe Bend is more than 5 times higher than that of the thick wall. In practice, 1-2 years after the use of ceramic lined composite steel pipe open were observed and measured, composite layer had no obvious wear and tear or fall off, in the same specification and unit length of pipe, ceramic lined composite steel pipe weight only the wear-resistant cast steel pipe or double metal composite pipe of about 1 / 2, the per meter project cost reduce 30-40%, about only two fifths of cast stone pipe and rare earth wear-Resistant Steel Pipe weight, per meter project cost reduced more than 20%.

The ceramic lined composite steel pipe used in high-temperature and corrosive places, its price only stainless steel tube, nickel titanium tube of a fraction of the ceramic lined composite steel pipe except for coal-fired power plants in addition to ash, slag, powder, powder, also widely used in following industries: 1, mine: 1.2 1.1 coal industry coal water slurry, coal washery, mines filling, coal mine metal mines: concentrate and tailings of pipeline transportation. 2, metallurgy: 2.1 steel plant iron blast furnace coal injection, slag and other pipeline, 2.2 steel conveyor iron alloy, furnace refining preferred pipeline. 3, cement factory: rotary kiln production line of wet raw slurry transportation, coal transportation, hoist material, concrete pipeline.

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Casting, forging, stamping, machining if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Surface treatment; Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step7: Package, Loading and Lashing when delivery;

Our service

Besides above the general specifications, we can also supply some specific Wear Resistant Pipe and other similar steel structure as clients' requirements.

Package and shipping

bulk package and bulk vessel transportation

container package and container transportation

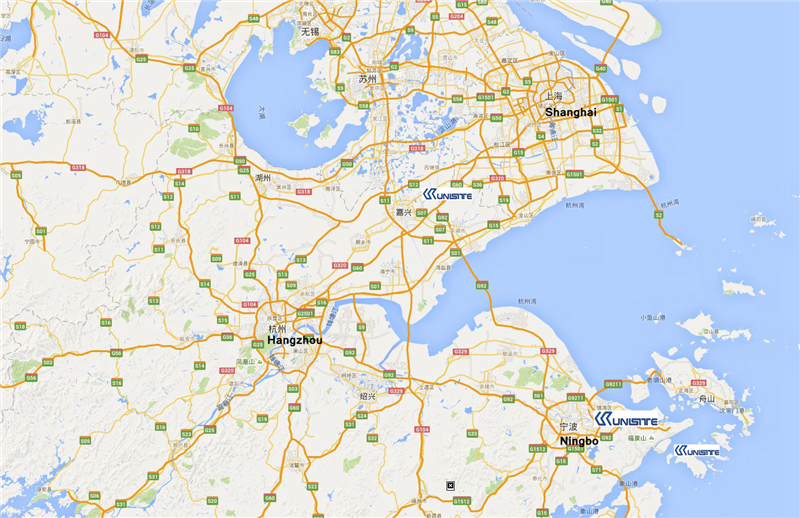

Location of head office and plants

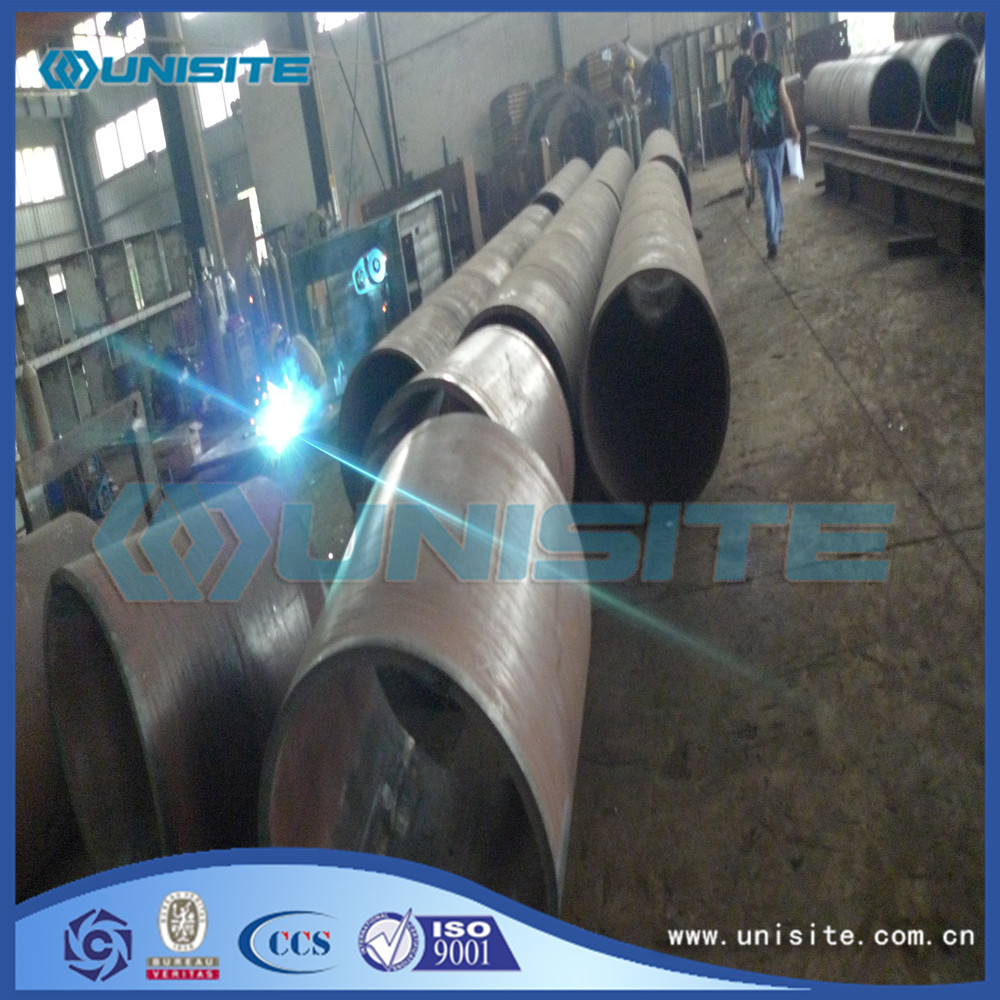

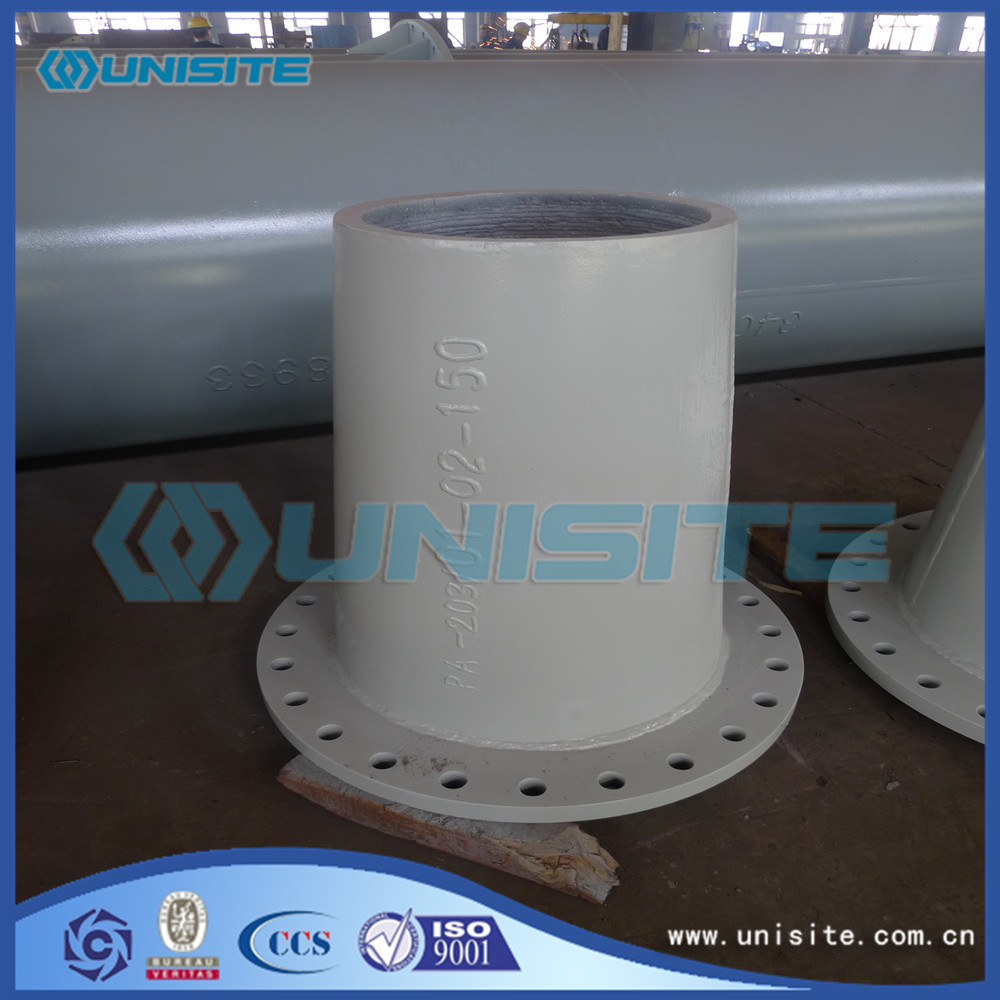

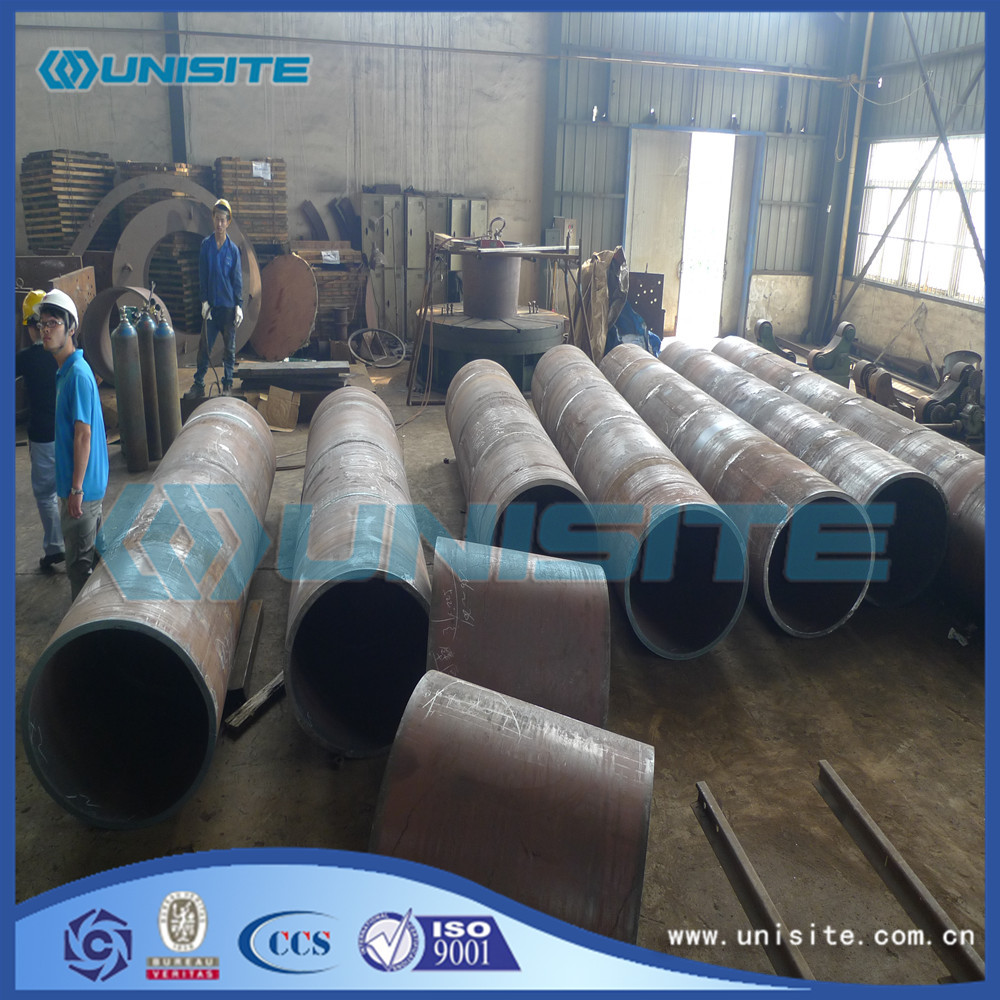

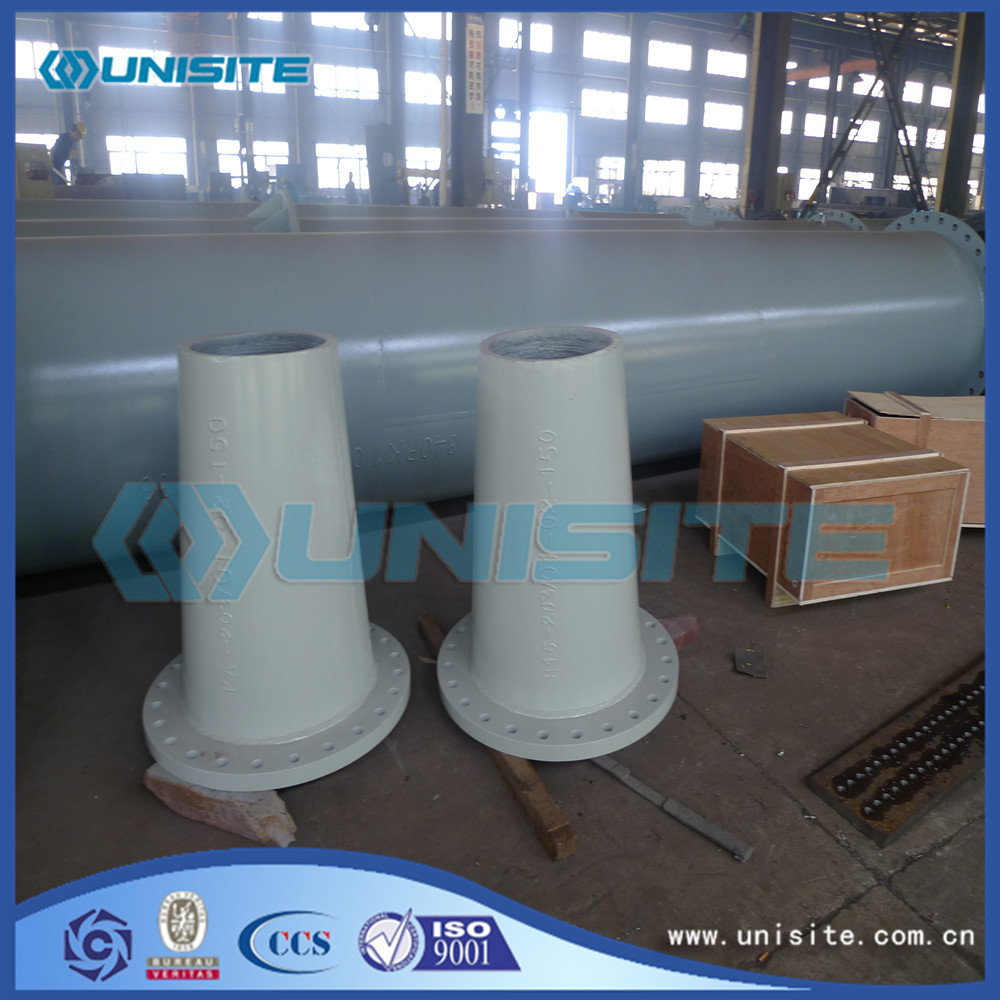

Photos of our Steel wear resistant loading pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Structural Pipes > Wear Resistant Pipe