Generally have two kinds of structure: first half open, is composed of a rear cover plate and blades, the structure, the efficiency of the Impeller lower, in order to improve the efficiency to be matched with a seal ring which can adjust clearance; another half open, is composed of a front cover plate and blades. The application and closed the same impeller sealing ring, efficiency and closed impeller is basically the same as the blades, and in addition to transport liquid, also has back blade or vice impeller seal. The semi open impeller is suitable for conveying liquid containing solid particles, fibers, etc.. Semi open impeller manufacturing is difficult, low cost, and adaptability, in the oil refining and chemical industry with a gradual increase in the application of centrifugal pump, and for the transport of water and water approximation of the liquid.

Photo of our Impeller:

Open impeller

Only blades and blades to strengthen the reinforcement, no front and back cover of the impeller (open impeller blade number less 2-5). Impeller efficiency is low, the application is less, mainly used for conveying high viscosity liquid, as well as slurry liquid.

Blade of centrifugal pump impeller is generally backward curved blade. There are two kinds of cylindrical and twisted, the application of twisted blades can reduce the load of the blade, and can improve the suction performance of centrifugal pump, improve the anti cavitation ability, but the manufacture is difficult, the cost is higher.

Centrifugal pump for oil refining and chemical industry requires impeller for casting or whole welding seam welding of the integral impeller. Special centrifugal pumps for chemical use in the manufacture of metal materials (such as iron and its alloys), which are used in the manufacture of poor performance, such as iron and its alloys. The geometric accuracy and surface finish of the welded impeller are superior to the casting impeller, which is beneficial to the improvement of the efficiency of the centrifugal pump.

Shape classification

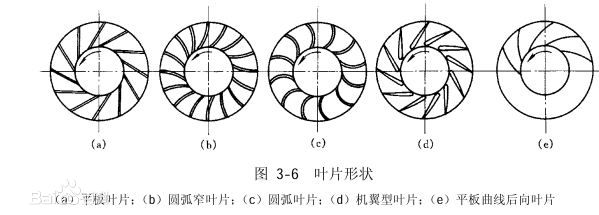

The shape of the blade centrifugal fan impeller has several single plate, arc type and wing type etc.. Airfoil blade has good aerodynamic characteristics, high efficiency, good strength and stiffness. The disadvantage is that the manufacturing process is complex, and when the transmission of high dust concentration of the gas, the blade is easy to wear, blade wear, the impurities into the blade, so that the impeller lost balance and vibration. The flat straight blade is simple, but the flow characteristics are poor, and the efficiency is quite close to the efficiency of the other working conditions when the flat curve is compared with the airfoil blade, and the efficiency is lower than the highest efficiency point.

Forward impeller

The front impeller generally adopts circular arc blade, and the rear direction impeller, the large fan adopts the airfoil blade, and the wind turbine of the coal fired boiler with low dust removal efficiency can adopt the circular arc type or the flat plate type blade. The centrifugal fan with flat blade is more.

(a) flat blade; (b) arc narrow blade; (c) arc blade; (d) wing blade; (E) flat curve back to blade

Compression impeller

Working round. The only component of the air flow in a centrifugal compressor. The most important parts on the rotor. Generally by the wheel, wheel cover and blade and other parts of the composition. Under the action of the impeller blades, the rotating speed of the leaf rotation, the gas is affected by the centrifugal force of the rotation, as well as in the impeller of the diffuser flow, so that it can be improved through the pressure of the impeller.

Requirements for impeller

(1) can be given a larger energy; (2) gas flows through the impeller loss should be small, namely the gas flows through the impeller efficiency to be high; (3) gas outflow impeller parameters when appropriate, the gas flowing behind the fixing element flow loss is smaller; (4) type of impeller can make or overall performance curves of the stable operating region and the efficiency range is wide. Normally divided into closed, semi open and open type impeller.

The impeller is composed of a wheel hub and a blade in a wind turbine. The wind passes through the impeller, drives the impeller to rotate, which drives the generator to rotate, and the wind energy is converted into electric energy. At this time, the rotating impeller with large enough on the windward side, to extract enough energy from the wind; at the same time, when the wind speed is too large, can automatically adjust the blade windward angle to avoid due to the stress and mechanical damage.

Impeller material

Cast iron, bronze, stainless steel, manganese bronze, Monel alloy, INCONEL, and non metal materials.

Non metallic materials

PPS plastic, phenolic resin, etc..