A trailing Suction Hopper Dredger or TSHD trails its Suction Pipe when working, and loads the dredge spoil into one or more hoppers in the vessel. When the hoppers are full the TSHD sails to a disposal area and either dumps the material through doors in the hull or pumps the material out of the hoppers. Generally these full block ships have a length between 40 to 130 m. The vessels are, highly manoeuvrable and they have a high installed power to operate the Dredging Equipment. Vessels operate regularly in shallow water conditions.

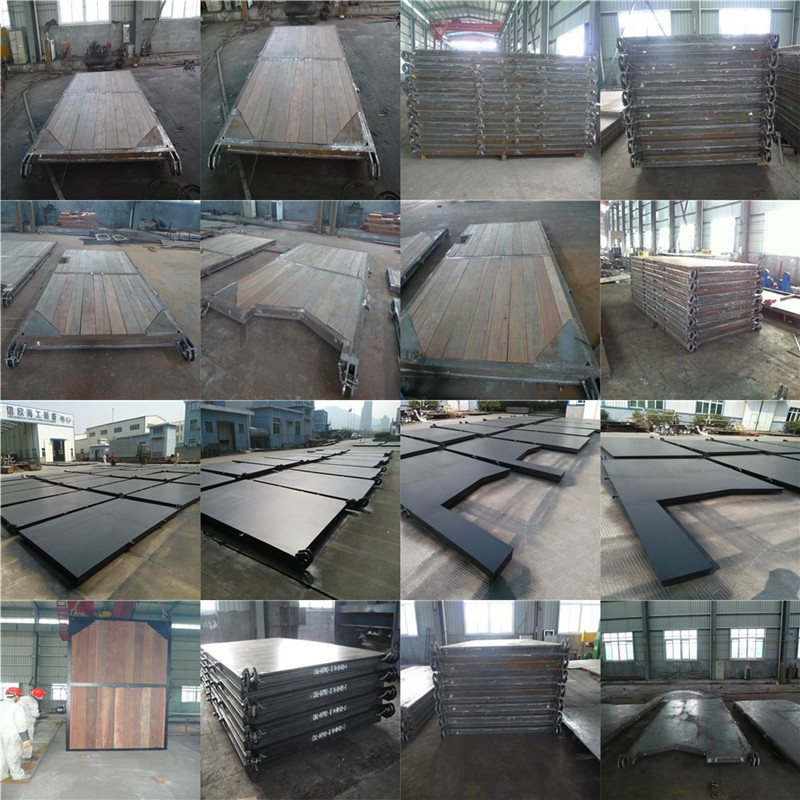

Photo of Hopper Panel

A. General

High-demanding welded and high strength Structural Steel Pipe with structure parts can be used for special Dredger parts., used in different position, mainly on deck.

We are proud of our produce line, equipment and skilled workers, we are able to manufacture steel structure and structural Steel Pipe pipes as per client's requirements.

B. Construction and procedure

The construction is to be built according to the drawing with rules of good workmanship.

Pipe with different length, angle, diameter, and with or without flanges.

C. Materials

All fabricated steelwork used in the construction of the dredger Structural Pipes will be to manufacturing standard of normal or classification society.

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

D. Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

E. Workmanship

The workmanship have good marine practice. Care are taken to ensure fair lines, smooth surfaces and neat welding.