Model No.: USA-041

Brand: UniSite

Dimension: As Per Drawing/order

Inspection: Material, Construction, Dimension, Welding Seam, N

Grade: 10#-45#, Q195-Q345, X42-X80, L245-L255 Or Other Ma

Standard: API 5L, BS 1387, GB/T 3091-2001, GB/T9711, ASTM A5

Certificate: API BV

Application: Marine Steel Structure And Dredging Field And Oil

Tolerance: High Accuracy(ISO2768, ISO5817, ISO13920); Detail:

Surface: Sa2.5 Blasted And Two Or Three Layers Painted With

Thickness: 5-60

Longitudinal Lined Seam Welded Pipe: Longitudinal Steel Seam Welded Pipes

Packaging: bulk package and bulk vessel transportation; frame container package and frame container transportation

Transportation: Ocean,Land

Place of Origin: china mainland(zhejiang)

Certificate: API/BV/ISO

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Straight Pipe should be made mechanical performance test and flattening test, flaring test, and to meet the requirements. Steel Pipe should be able to withstand a certain internal pressure, if necessary, 2.5Mpa pressure test, to maintain a minute without leakage. Eddy current testing is allowed to replace hydrostatic test.

Welding of Longitudinal pipe

welding

Straight seam pipe generally high-frequency welding, high frequency welding is a kind of induction welding (or pressure contact welding), it does not need to weld filler, weld spatter, welding heat affected zone is narrow, beautiful welding molding, welding, the advantages of good mechanical performance, so in the production of steel by wide application. According to the principle of electromagnetic induction and the exchange charge in the conductor tends to skin effect and proximity effect and eddy current heat effect, the edge weld steel local heating to a molten state, through the roller extrusion, the butt weld the intergranular bonding, so as to achieve the purpose of seam welding, cooling after the formation of a strong straight seam welding.

Weld gap

Will strip into the welded pipe unit, by the multi-channel roller rolling, strip gradually rolled up, forming the opening gap circular tube billet, adjusting the extrusion roller pressure, weld gap control in 1 ~ 3mm, and the weld ends flush. If the gap is too large, resulting in a reduction in the proximity effect, the eddy heat is insufficient, the welding seam between the poor bonding and produce no fusion or cracking. Such as the gap is caused by proximity effect increases, large welding heat, resulting in weld burning, or weld by extrusion, rolling form the pit affecting weld surface quality.

welding temperature

Low carbon steel material, welding temperature control in 1250~1460 C, can meet the pipe wall thickness 3~5mm welding penetration requirements. Welding temperature is mainly controlled by adjusting the high frequency eddy current heat power and welding speed. When insufficient heat input by heating the weld edge is not up to the welding temperature, metal structure remains solid, the formation of fusion or incomplete penetration; when the heat input is too large, heating the weld edge over welding temperature, burn off or droplet, molten hole can be formed in the weld.

Our service

Besides above the general specifications, we can also supply some specific pipes and other similar steel structure as clients' requirements.

Package and shipping

bulk package and bulk vessel transportation

frame container package and frame container transportation

To produce our products with strict standards of military products

Our team have rich experience in military marine products with military standard.

Outstanding in multiple fields

Besides dredging and marine engineering, we are also specialized in providing comprehensive service of municipal engineering, mechanical engineering, oilfield projects and environmental remediation projects.

Assure for large production capacity with many advanced equipment

Integrate all resources, UniSite have large advanced equipment and is able to do most large products of marine products including pontoons

Bending machining, rolling machine with 150mm, SAW equipment, manual welding equipment, Laser Thermometer, Electrode dryer, cutting machine, milling machine, electrical element, big Welding roller stand, Box -type electric furnace, special inspection tools, Lifting Gantry 200T, 100T, floating crane 1200T-

With professionalism, vitality, innovation, respect, team spirit, UniSite culture (corporate values, corporate philosophy and behavior shaping) is continuously developing, along with our company from its foundation.

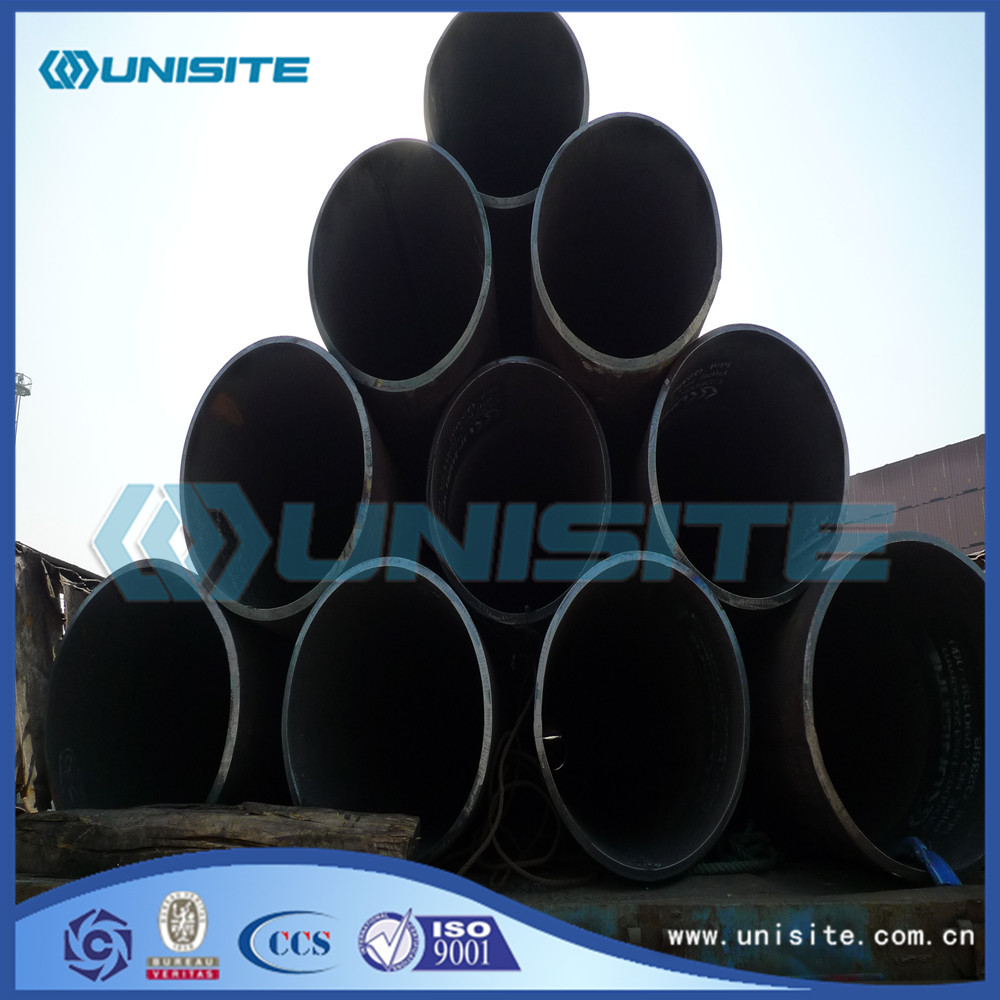

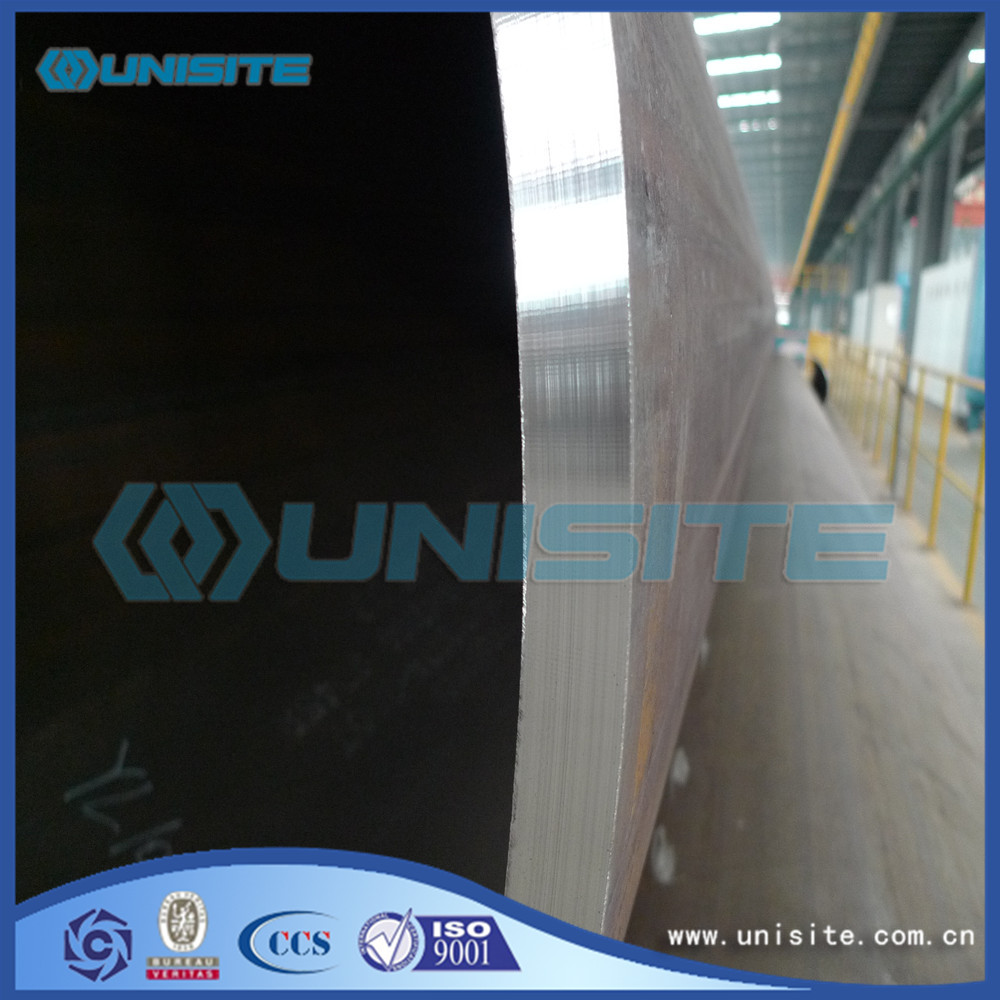

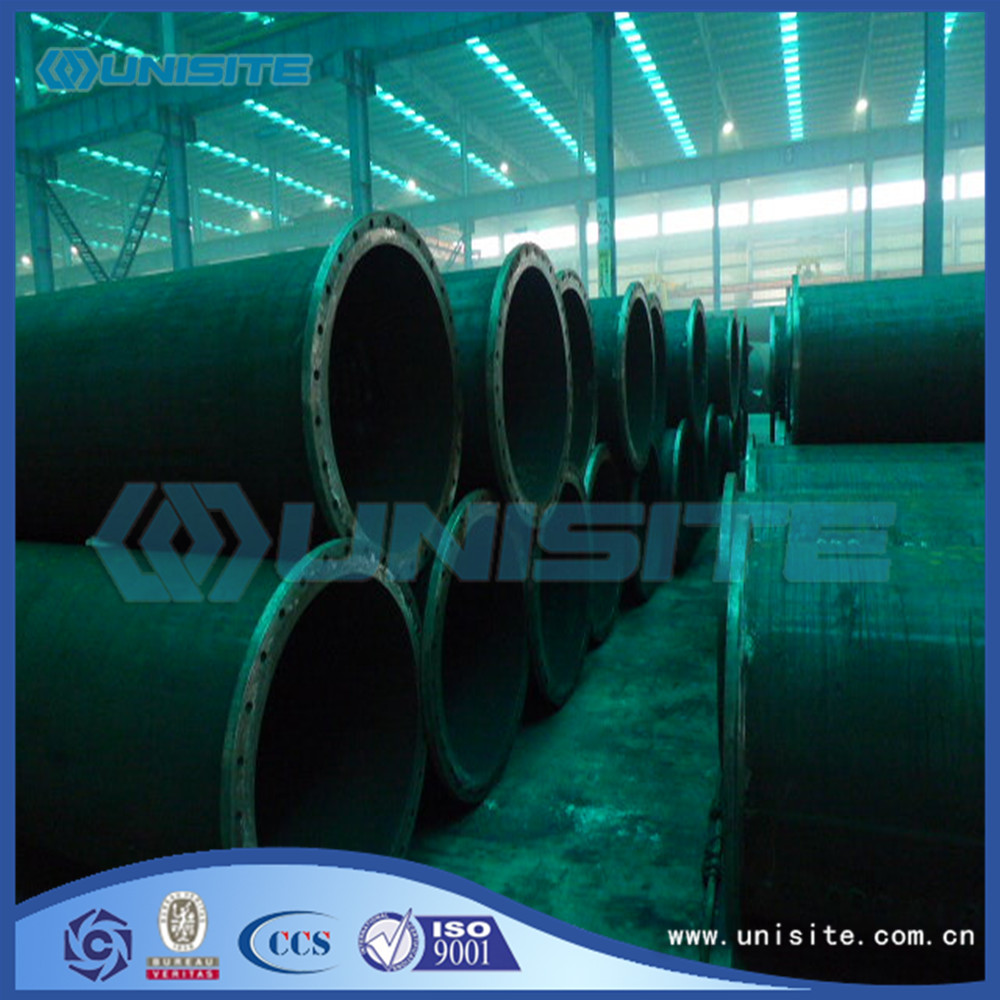

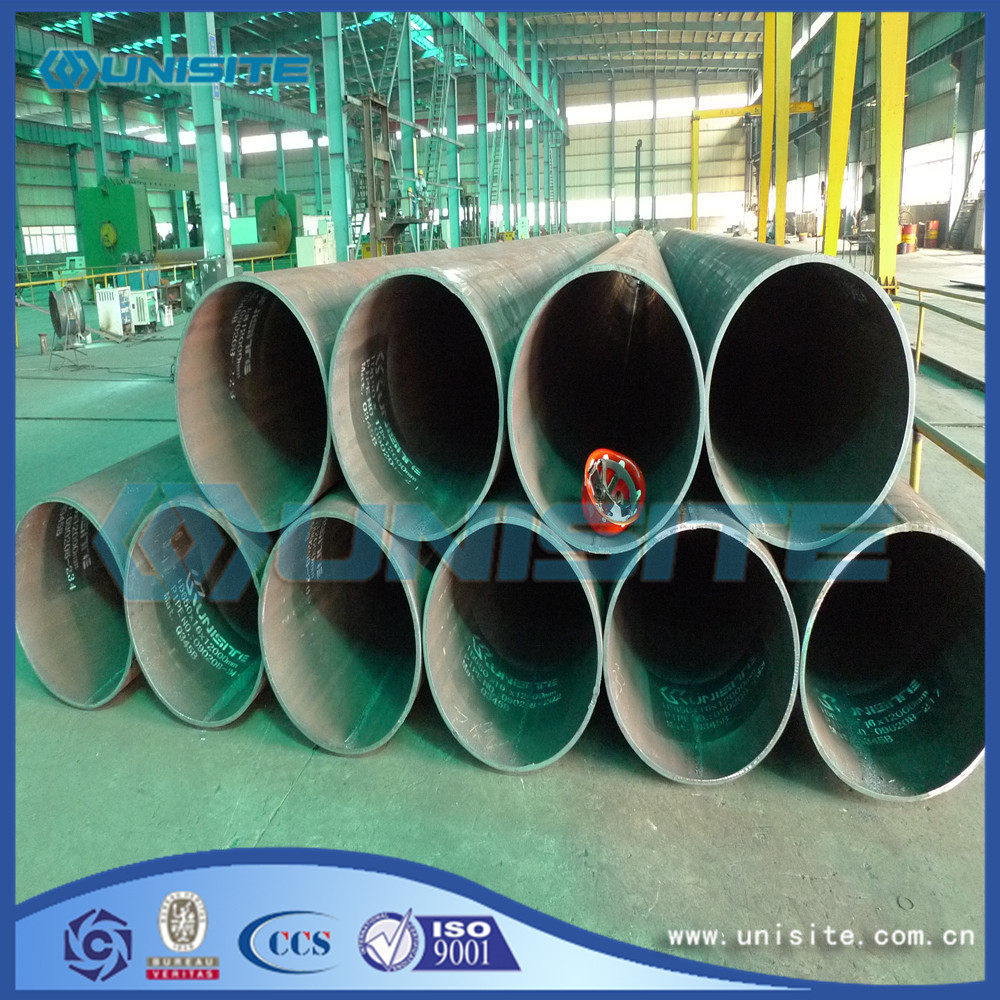

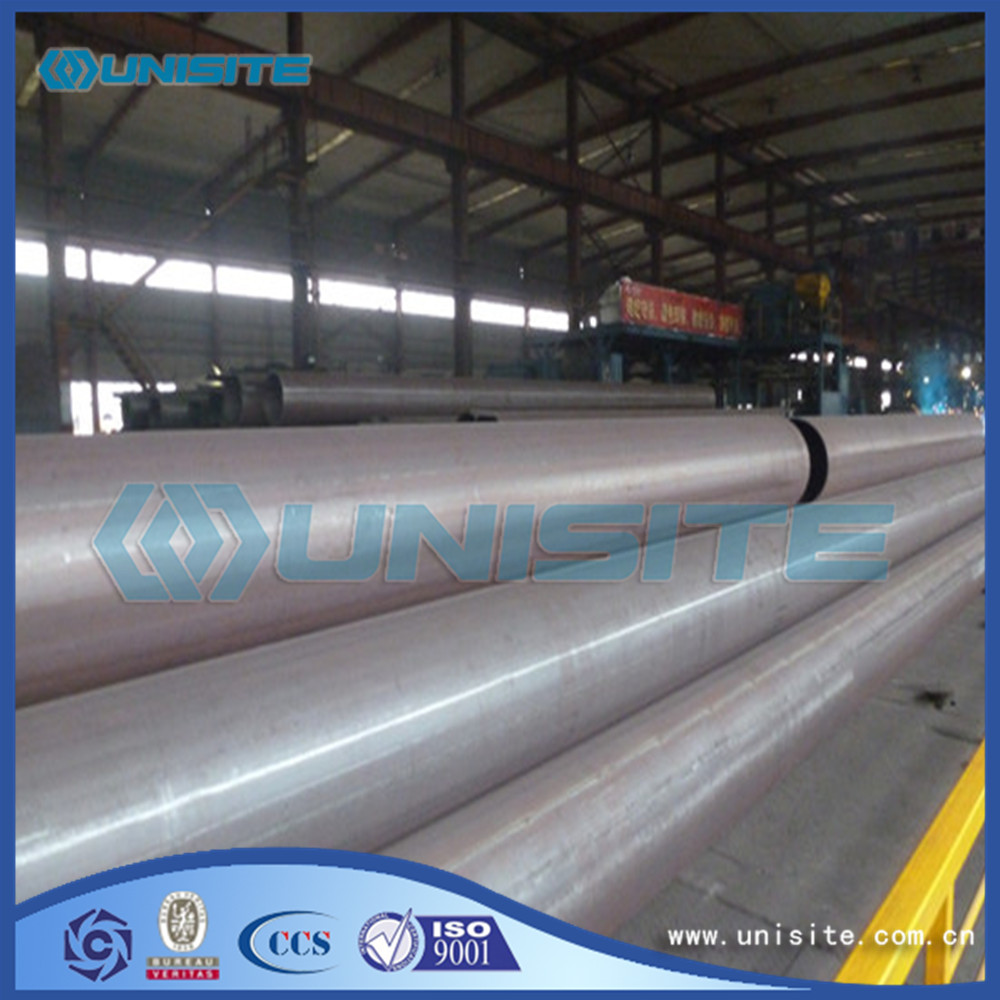

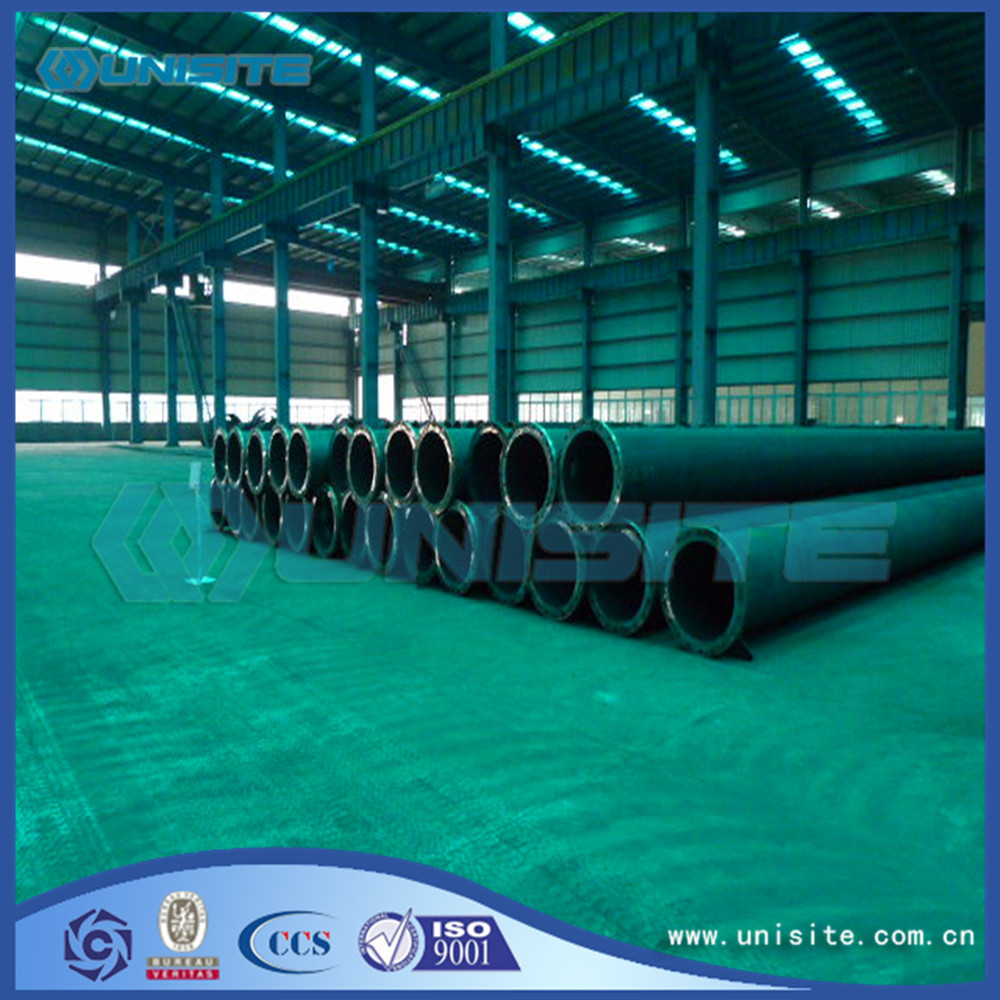

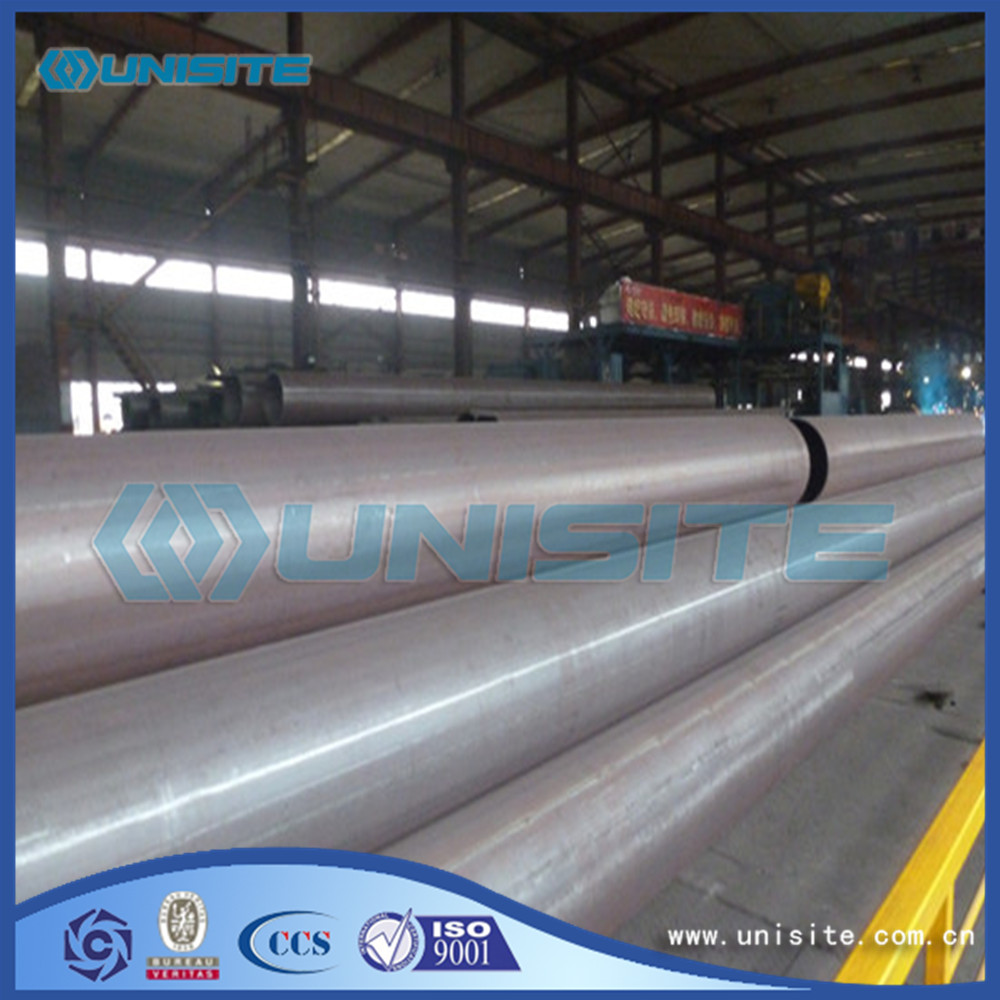

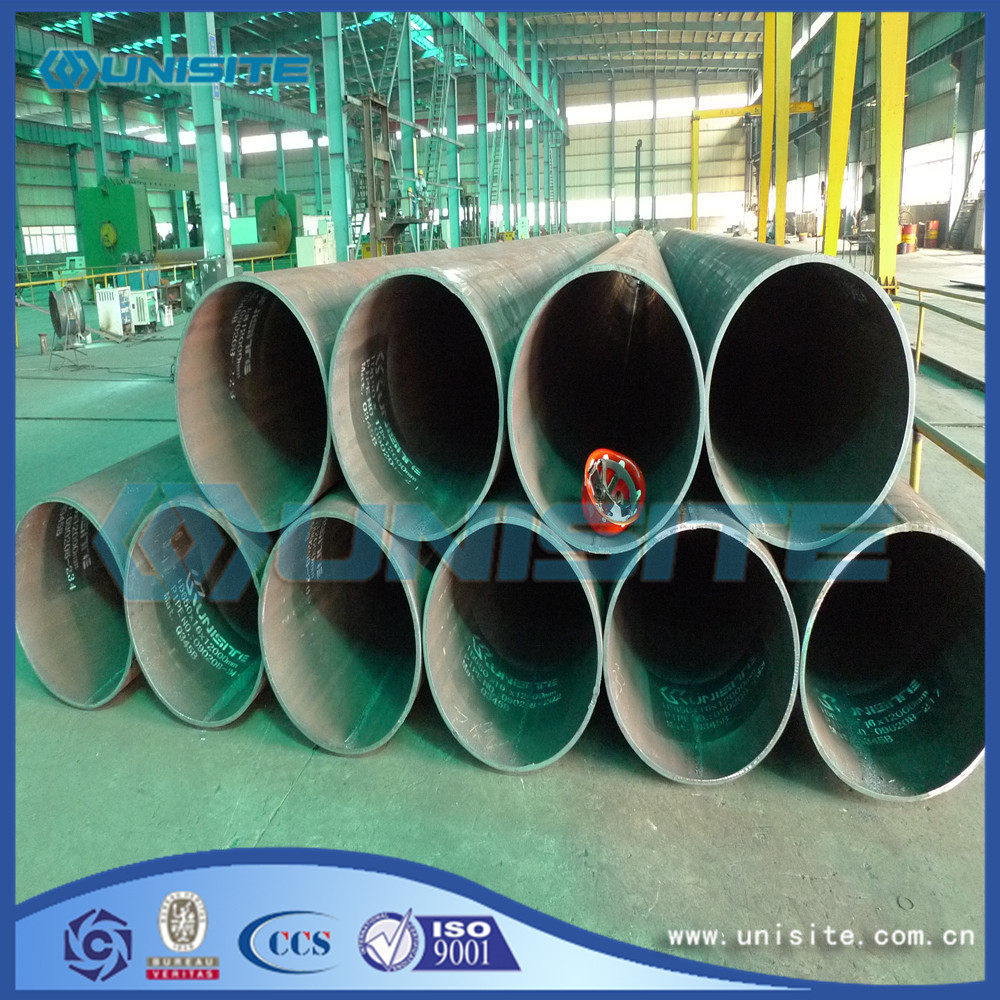

Photos of our Longitudinal steel seam Welded Pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Longitudinal Pipe