Model No.: USA-067

Brand: UniSite

Dimension: As Per Drawing/order

Inspection: Material, Construction, Dimension, Welding Seam, N

Grade: 10#-45#, Q195-Q345, X42-X80, L245-L255 Or Other Ma

Standard: API 5L, BS 1387, GB/T 3091-2001, GB/T9711, ASTM A5

Certificate: API BV

Application: Marine Steel Structure And Dredging Field And Oil

Tolerance: High Accuracy(ISO2768, ISO5817, ISO13920); Detail:

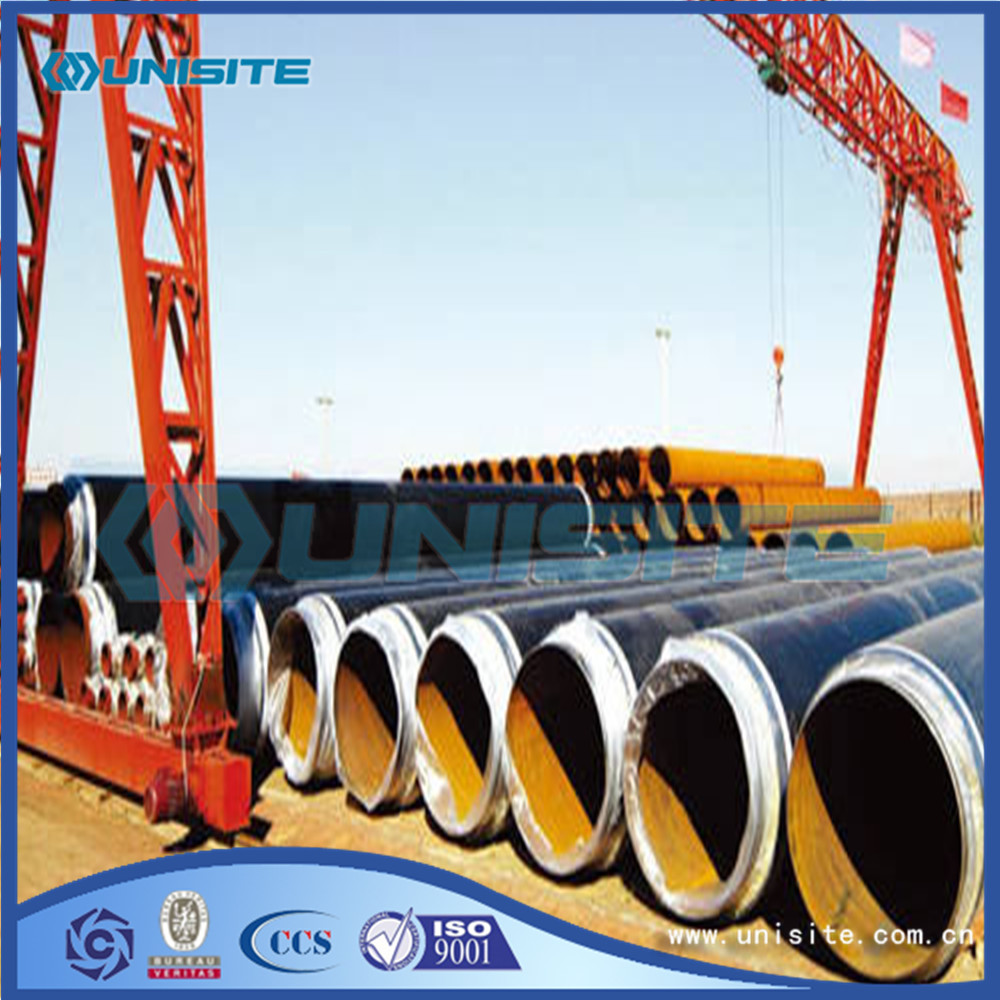

Surface: Sa2.5 Blasted And Two Or Three Layers Painted With

Thickness: 5-60

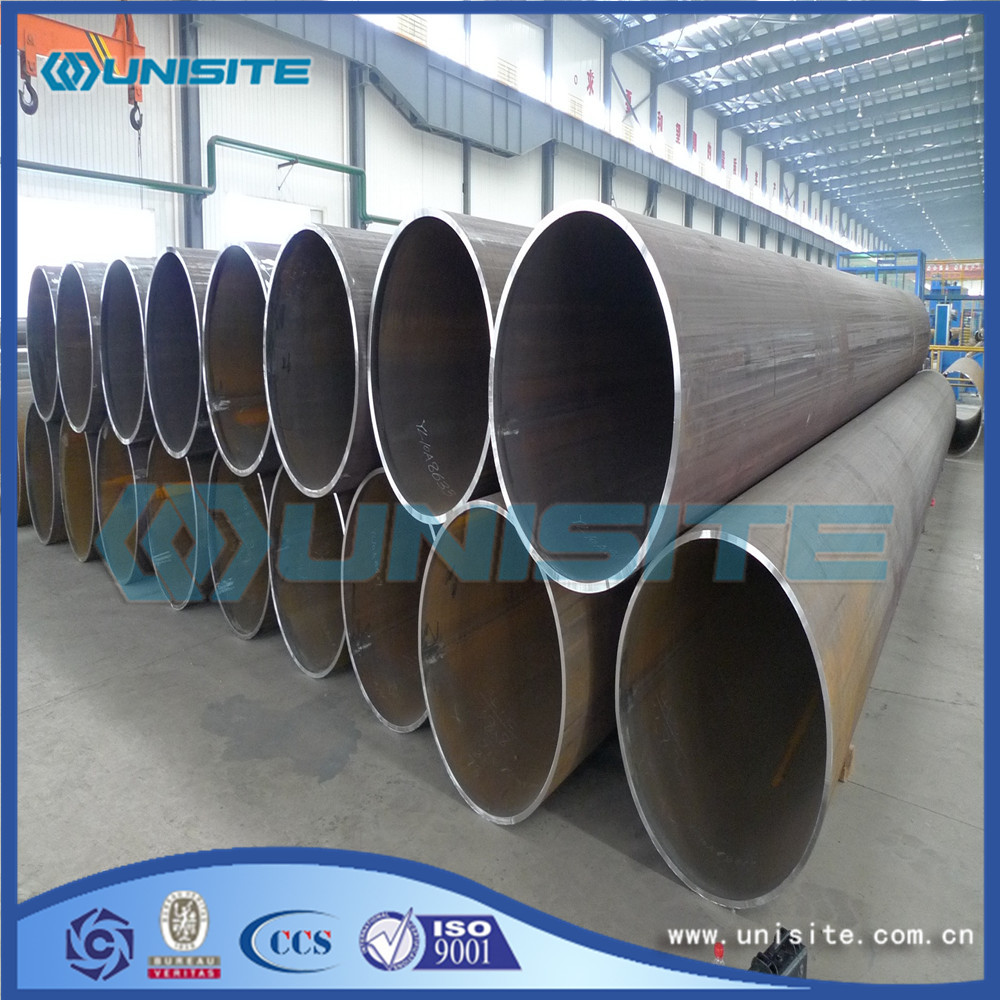

Longitudinal Steel Welded Pipe: Longitudinal Welded Steel Pipes

Packaging: bulk package and bulk vessel transportation; frame container package and frame container transportation

Transportation: Ocean,Land

Place of Origin: china mainland(zhejiang)

Certificate: API/BV/ISO

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

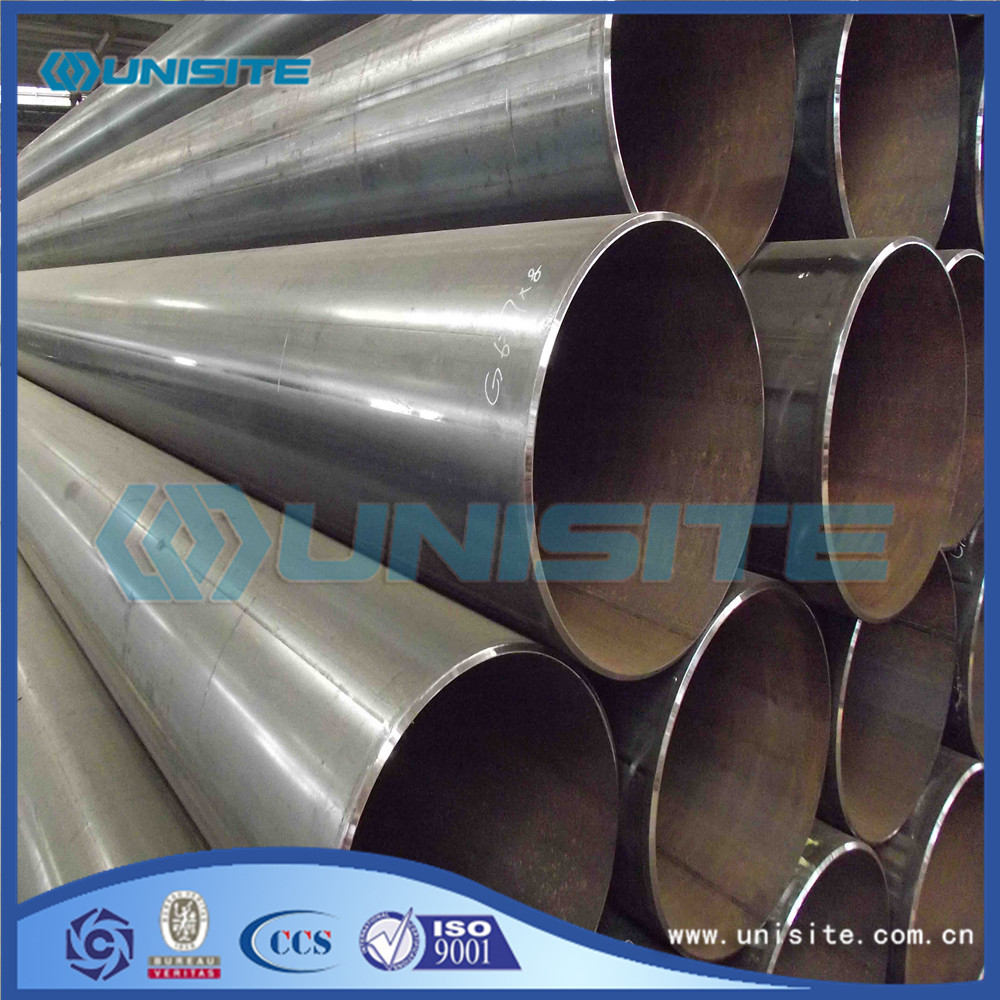

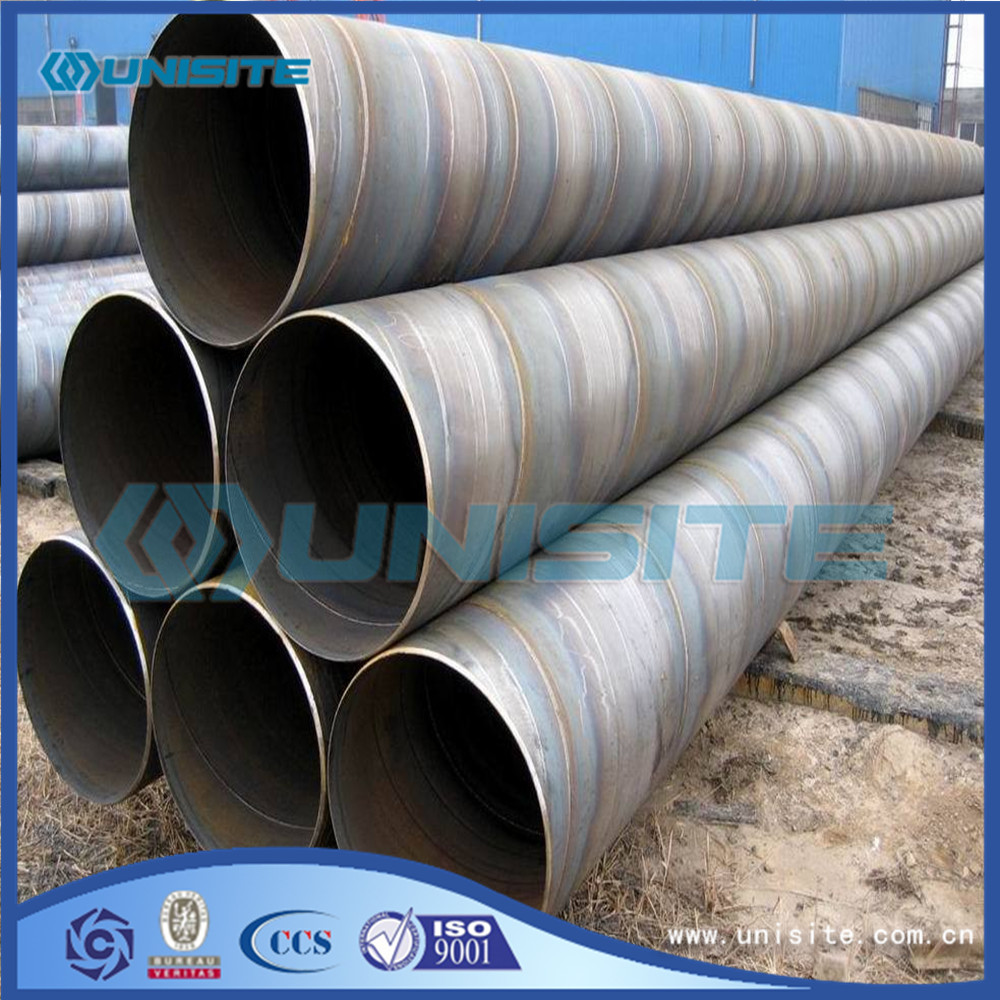

Welding Steel Pipe production process is simple, the production efficiency is high, the variety of specifications, equipment investment is low, but the general strength is lower than the Seamless Steel Pipe. Since the thirties of the 20th century, with the rapid development of high quality cold rolling strip steel rolling production and progress of welding and inspection technology, continuously improve the quality of weld, welding steel pipe specifications are increasing and in more and more fields instead of the seamless steel pipe. According to the form of Welded Steel Pipe weld is divided into longitudinal and spiral welded pipe.

Properties of Steel Pipe

Steel has salient properties that can be utilized to advantage in buried pipelines. The following are desirable requirements of buried, pressurized pipe. These requirements can be achieved by welded steel pipe.

1. Strength – The high strength of steel results in lightweight pipe that can resist internal pressure, and can also resist external pressure when the pipe is not pressurized. Minimum yield strength of most pipe-grade steel is 42,000 psi (290 MPa). Higher strength steels are available. Longitudinal strength (beam strength) of steel pipe is of value wherever the pipe is subjected to variable loads or is supported on non-uniform bedding, or where the pipe is buried in soil that slips or settles. Because joints can be welded, steel pressure pipe usually does not require thrust blocks at special sections (valves, tees, elbows, reducers, etc.) However, thrust restraint is required in gasketed, pressure pipelines. Longitudinal tension in buried pipe is caused by any longitudinal beam action (bending), internal pressure and decrease in temperature. The high strength of steel and the low Poisson ratio and coefficient of thermal expansion/contraction, combine to make steel pipe relatively resistant to longitudinal

stresses.

2. Ease of installation – During handling and installation of buried pipe, the pipe ring must be stiff enough to hold its shape to near circular. The modulus of elasticity of steel is 30,000,000 psi (207 GPa). Materials with lower moduli must have thicker walls to provide equivalent stiffness. Under external fluid pressure, ring stiffness is needed to prevent collapse. If it is necessary to

increase ring stiffness, there are a multitude of options available to the designer. Because of its longitudinal strength and relatively smooth outer surface, steel pipe lends itself to installation by microtunneling. Where native soil is recycled as flowable fill, long sections can be held down during pouring of bedding and embedment.

3. Long service life – The service life of steel pipe depends upon rates of external corrosion and internal abrasion. The service life can be increased by the use of proper coatings and cathodic protection. Technology for control of corrosion is available and well documented. Abrasion can be caused by grit in the fluid flow. Protective linings reduce abrasion. Historical service life is shown in Appendix A. If increased flow is required at some future time beyond the designed service life of the pipe, the wide margin of safety in the design of steel pipe often makes it possible to increase pressure and still keep stresses within reasonable limits. With attention to coatings and cathodic protection, the service life of steel pipe can be extended indefinitely.

4. Economy – The final cost of buried pipe includes: pipe, embedment, transportation, installation, operation, maintenance, repair, modification and risk. Transporting steel pipe is cost effective, especially in large diameters, because of thin wall and light weight. (Requirements for blocks and stulls are minimal.) Installing steel pipe is expedited by light weight. Long pipe sections

reduce the number of welds (or the number of bell and spigot joints that must be gasketed and stabbed). In the event of damage, steel pipe can often be repaired on site. In the event of a massive soil wash-out, welded steel pipe sections tend to hold together and minimize the disaster caused by a break in a pipeline.

Our service

Besides above the general specifications, we can also supply some specific pipes and other similar steel structure as clients' requirements.

Package and shipping

bulk package and bulk vessel transportation

frame container package and frame container transportation

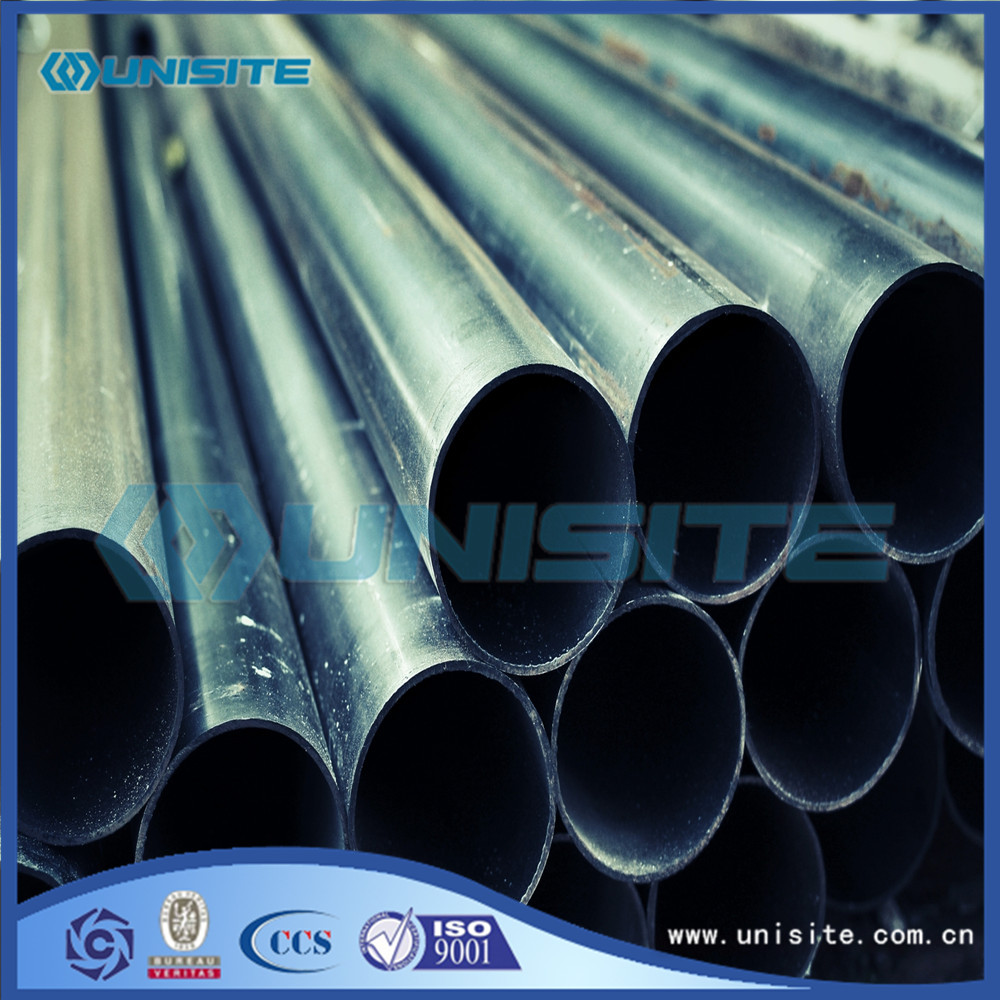

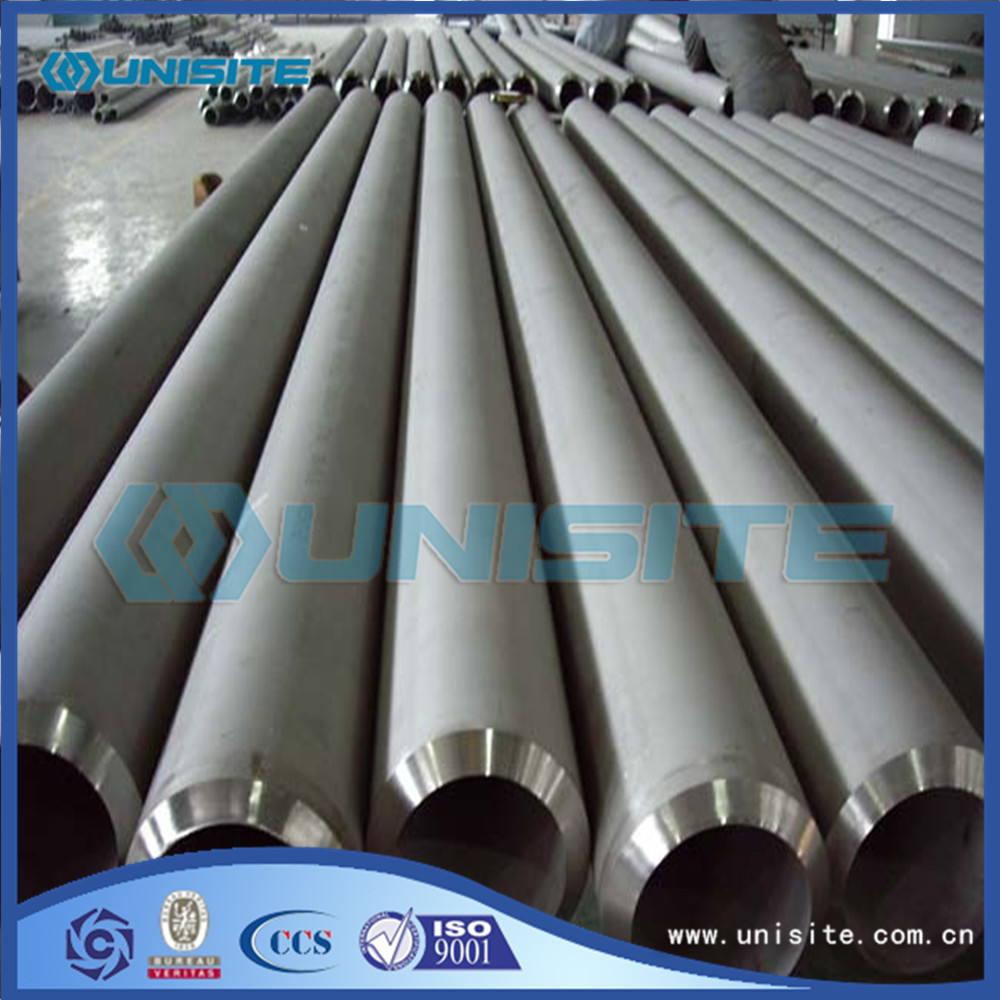

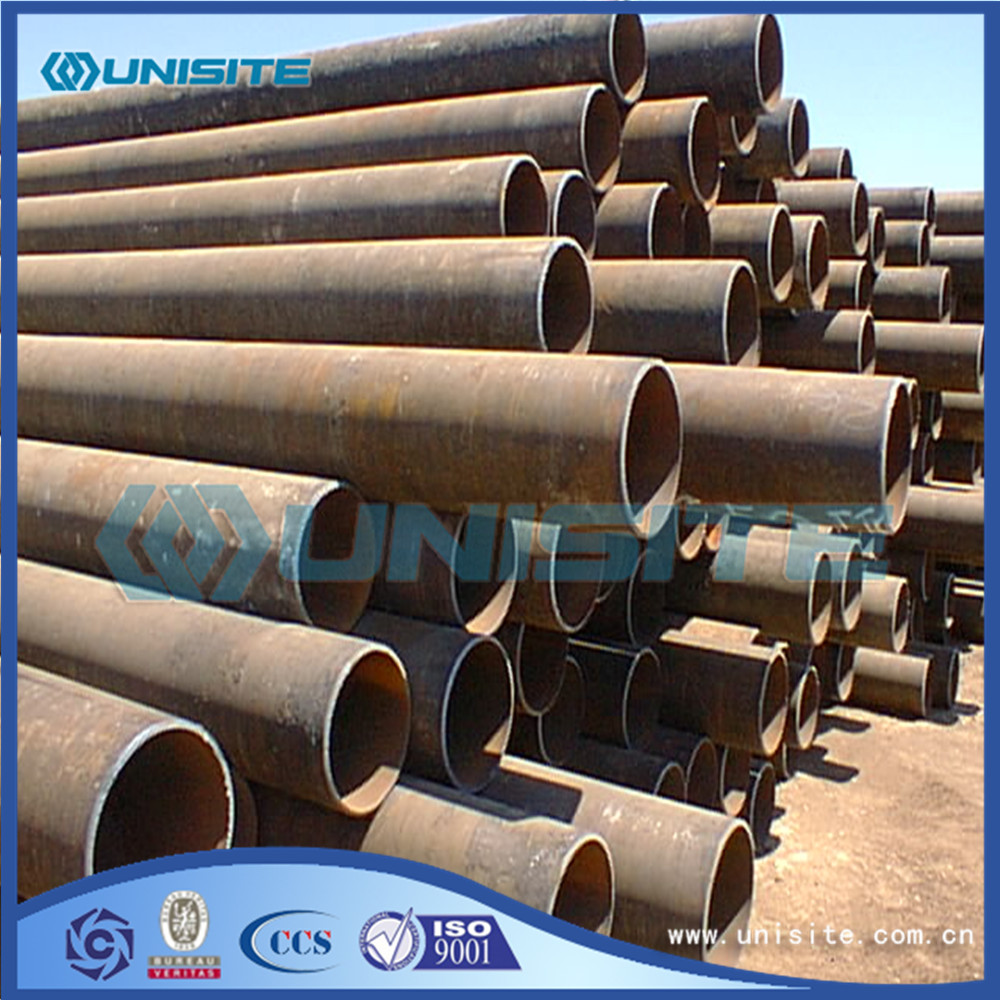

Photos of our Welded steel pipes for sale

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Steel Pipe